How to Make a 3D Printed RC Plane: A Step-by-Step Guide

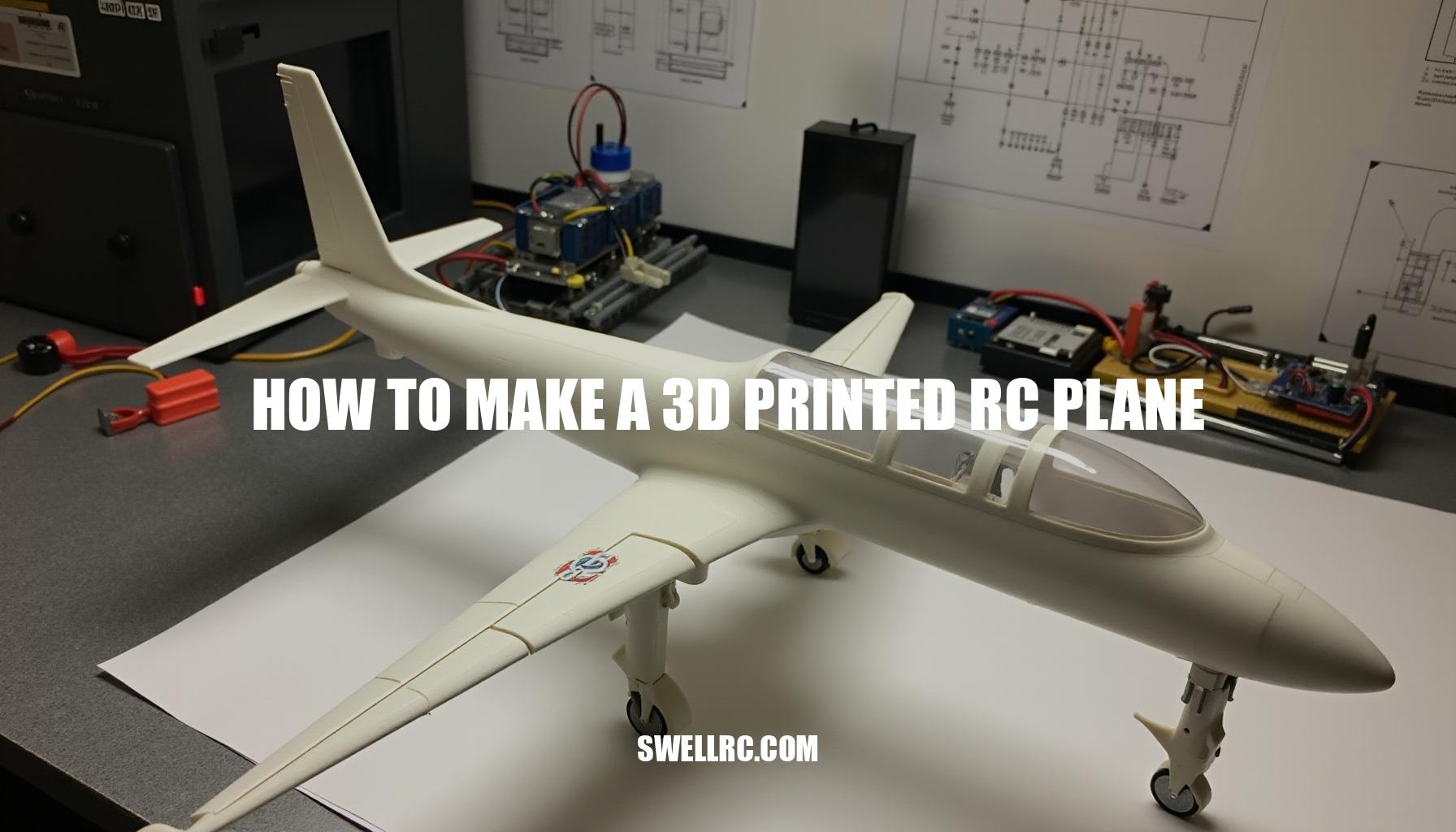

I still remember the electrifying moment when I realized that I could transform a simple CAD sketch into a flying airframe over a single weekend—it felt like launching my very own personal moonshot. Thanks to desktop 3D printers, the days of wrestling with complex balsa jigs to shape airfoils, fuselages, and control surfaces are behind us. Now, hobbyists can effortlessly customize 3D printed RC fuselage components, tailoring every detail to their vision.

The RC scene has never been more vibrant, ranging from minimalist paper builds like the charming RC paper aeroplane to ambitious multi-rotor concepts and fully printed airframes. With lightweight RC building materials and a bit of creativity, the frontier of 3D printing RC models welcomes everyone eager to dive in. My thesis is clear: with the right plan, any motivated beginner can design, print, assemble, and fly their very own radio controlled airplane—bringing the joy of DIY RC planes to new heights.

Understanding the design: blueprinting your 3D RC plane

When embarking on an RC plane design project, establishing a clear idea-to-STL workflow is essential for success. Start by selecting the right RC plane design software based on your needs: Fusion 360 offers parametric precision ideal for iterative tweaks, SolidWorks excels with advanced surfacing for aerodynamic shapes, while TinkerCAD is perfect for beginners wanting a faster learning curve.

Next, define your mission profile—is your model a slow flyer, a sport aerobat, or a glider? This decision critically influences wing loading, airfoil selection, and control surface sizing, establishing foundational design parameters.

Engineering proper weight distribution is crucial, especially in a 3D printed RC fuselage. Position your battery and motor to meet center of gravity targets, typically around 25–33% back from the wing’s leading edge. This is vital when figuring out how to balance a 3D printed RC aircraft for stable flight.

Next comes part segmentation: divide your airframe into printable sections like nose, fuselage midsection, tail boom, and wing panels, incorporating build-in joiners and alignment keys for effortless assembly. Don’t forget to add reinforcement channels within wings and spars designed for carbon rods—this addresses strength concerns without adding excessive weight.

Before finalizing, export watertight STL files and test-print small coupons. This validates your tolerances and printability. Many wonder, can you 3D print wings for RC planes? With proper segmentation and reinforcement, it’s absolutely feasible enabling complex geometries and lightweight construction.

For free STL resources, explore manufacturer libraries, community repositories like Thingiverse or MyMiniFactory, and open-source RC groups that share tailored parts for various models.

| Resource Type | Examples | Notes |

|---|---|---|

| Manufacturer Libraries | RCBrands STL Downloads | Official parts for specific models |

| Community Repositories | Thingiverse, MyMiniFactory | User-created, wide variety |

| Open-source RC Groups | RC Groups Forums, GitHub repos | Collaborative designs, modifiable files |

For an innovative twist, consider adapting drone parts into fixed-wing builds. This cross-pollination approach leverages compact motors and electronic speed controllers optimized for drones, reducing weight and boosting efficiency. Complement that by reviewing traditional framing fundamentals from how to build a balsa wood RC airplane, which emphasizes structure integrity and weight control—valuable lessons when evolving 3D printed designs.

Early design mistakes are part of the learning curve. Common pitfalls include tail-heavy prototypes leading to instability and underbuilt spars unable to withstand flight stresses. Correct these by repositioning components for proper center of gravity and reinforcing wing spars with carbon rods or thicker infills.

Iterative test flights combined with adjusted CAD models greatly improve final performance.

Adopting this holistic workflow—careful software choice, mission-driven design, strategic weight distribution, thoughtful part segmentation, and learning from both digital and traditional RC plane building—ensures your 3D printed RC aircraft will fly beautifully and stand out in both craftsmanship and innovation.

Printing and materials: what works best for airborne performance

When selecting PLA and ABS filaments for 3D printing RC airplane components, it’s crucial to understand the benefits and limitations of each material to optimize performance and durability. PLA is favored for its ease of use and ability to deliver crisp surface details; however, it should be kept out of hot sun exposure due to lower heat resistance. PETG offers tougher parts with slightly increased weight, making it suitable for components requiring a balance of strength and flexibility.

ABS excels in heat resistance but necessitates an enclosed printing environment to avoid warping. Specialized materials like LW-PLA are ideal for ultra-light structures such as wings and fuselage skins because they foam during printing, reducing weight substantially.

For print settings, a layer height between 0.2 and 0.28 mm is recommended to balance print speed and surface quality. Utilize 2–3 perimeters for general skins and increase to 4 or more for load-bearing sections to enhance strength. Sparse infill patterns like gyroid or lines at 5–15% density typically suffice for non-structural parts.

Conversely, foamed LW-PLA shells perform best with thicker walls paired with minimal (0–5%) infill, preserving ultra-lightweight characteristics.

Orientation plays a vital role in print durability and strength. Print spars and load-bearing tabs aligned so that layer lines run along the load path to maximize strength. Control horns should be printed flat to enhance shear strength, preventing premature failures in these critical areas.

Effective support strategies help achieve clean prints and simplify assembly. Consider splitting large parts to reduce support material and print time, or use custom tree supports to minimize contact marks. During assembly, integrate magnets, heat-set inserts, and embedded nut traps to streamline construction and improve part fastening reliability.

Contrasting 3D printed builds with flat-foam designs, such as those illustrated in 3D flat foam airplanes, reveals different trade-offs in weight and durability. Ultra-minimal weight approaches discussed in how to make super light RC indoor planes emphasize extreme weight saving techniques, while cardboard prototypes (see cardboard RC plane) offer quick and inexpensive concept testing.

| Filament | Strength | Weight | Heat Resistance | Best Use |

|---|---|---|---|---|

| PLA | Moderate | Light | Low (avoid hot sun) | Easy prints, crisp surfaces |

| PETG | High (tough) | Moderate | Moderate | Durable parts with slight extra weight |

| ABS | High | Moderate | High (needs enclosure) | Heat-resistant, structural parts |

| LW-PLA | Low (foamed) | Ultra-light | Low | Wings, fuselage skins |

By carefully balancing filament choice, print orientation strength, and optimized infill—which aligns directly with how strong should infill be for RC plane parts—builders can craft lightweight RC airplanes with superior performance. Incorporating these guidelines with an understanding of lightweight RC building materials empowers makers to tailor their approach, whether creating robust prototypes or ultra-light indoor flyers.

Assembly and electronics integration

Follow this detailed assembly sequence for your radio controlled airplanes to ensure optimal performance and reliability:

- Dry-fit fuselage sections: Temporarily assemble the fuselage parts to check alignment. Use thin CA adhesive applied with a wick along the seams or opt for plastic-weld adhesives for strong bonds. Reinforce the joins internally with pins or carbon dowels to enhance structural integrity.

- Install carbon spars in wings: Place the spars carefully and verify the wing’s dihedral and incidence angles before the adhesive cures to maintain proper aerodynamic balance.

- Hinge and test control surfaces: Attach control surfaces using appropriate hinges, ensuring free movement with minimal slop. This is a crucial part of effective servo motor setup for RC planes.

- Mount motor to a printed or aluminum firewall: Secure the motor and validate the thrust line visually. Add washers behind the firewall if you need to adjust for down or right thrust angles to compensate for torque effects.

- Install servos: Center each servo before connecting pushrods. Test the linkage system thoroughly to avoid binding at full throws, ensuring precise control response.

- Wire ESC, receiver, and battery: Route wires neatly to prevent interference between components. Verify correct channel mapping for seamless communication within your ESC and receiver wiring setup.

- Set preliminary center of gravity (CG): Use the battery as movable ballast to find the optimal CG position. Mark the battery tray for repeatable placement during flights—this step is vital for stable center of gravity testing.

- Perform radio range test and control-direction check: Ensure reliable signal reception and confirm that all controls respond correctly to radio inputs before the maiden flight.

Here’s a concise checklist of essential components for your assembly:

- Motor sized appropriately for the airframe

- ESC (Electronic Speed Controller) with adequate headroom

- Propeller compatible with motor and airframe

- 2–4 micro servos for control surfaces

- Receiver matched to your transmitter

- LiPo battery with sufficient capacity and discharge rate

- Linkages and connectors for all control surfaces

For enthusiasts interested in rotary-wing crossover techniques, such as specialized mounts, balance considerations, and wiring practices, consult our detailed guide on how to make a RC helicopter. This resource complements the fixed-wing assembly sequence outlined here.

Note to designer: Please insert an exploded diagram of the fuselage joinery and a wiring layout schematic to visually support these instructions and facilitate ease of assembly.

Flight testing and tuning

Ensuring a successful and safe maiden flight for your 3D printed RC aircraft requires a methodical approach. First, inspect the airframe meticulously; confirm all fasteners are secure, check control throws, and verify the center of gravity (CG) is accurate, which is crucial for how to balance a 3D printed RC aircraft. Next, choose a calm day and a wide field to minimize risk, and start your flight testing checklist with a low-power glide test to assess basic stability.

For the maiden flight, apply modest throttle and climb to a safe altitude, then proceed with radio trim and tuning of pitch, roll, and yaw to maintain control. If issues arise, diagnose them carefully: a tail wag often indicates insufficient vertical fin stiffness, wing drop suggests incidence or warp issues, and porpoising usually means the CG is too far aft or elevator inputs are excessive. These steps align closely with key tips on how to ensure flight stability in 3D printed models.

Subsequently, tune your control rates and add exponential (expo) based on your skill level. If you notice adverse yaw, consider dialing in differential ailerons for smoother turns. Equally important is to select and balance your propeller correctly to optimize thrust and efficiency; proper propeller choice can significantly impact performance—refer to reliable guides like “How to Choose a Propeller for RC Plane” (https://www.swellrc.com/how-to-choose-a-propeller-for-rc-plane/).

Finally, build your piloting skills progressively by practicing approaches, stalls, and recovery maneuvers. For structured training paths and aerobatic groundwork, resources like “How to Fly 3D RC Airplane” (https://www.swellrc.com/how-to-fly-3d-rc-airplane/) offer excellent guidance.

To summarize troubleshooting during early flights, consider this table:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Tail Wag | Vertical fin too flexible | Reinforce vertical stabilizer for stiffness |

| Wing Drop | Incorrect wing incidence or wing warp | Re-examine wing alignment and adjust incidence |

| Porpoising | CG too far aft or excessive elevator throw | Shift battery forward or reduce elevator input |

| Adverse Yaw | Unbalanced aileron differential | Implement differential aileron settings |

Going further: upgrades, variations, and experimental builds

Once you’ve achieved your first successful 3D printing RC models flight, it’s essential to embrace experimentation to push the boundaries of your design and performance. Consider adopting modular RC plane design concepts such as modular wings with interchangeable spans or printed swappable power pods that enable quick upgrades and variations tailored to different flying conditions. Introducing carbon strip or glass tape reinforcements can significantly enhance structural integrity without adding much weight, a smart approach when working with lightweight RC building materials.

Hybrid builds, like combining printed formers with foam or balsa skins, open up exciting avenues for performance and durability enhancements. You might also explore using LW-PLA skins reinforced with internal lattice ribs to achieve a lightweight yet rigid airframe. Adding quick-change landing gear and float options further diversifies your model’s capabilities for land and water operations.

Scaling your aircraft offers insights into aerodynamic changes, while iterating airfoil designs through 3D printing allows for fine-tuned lift and stability. Printing dedicated jigs aids in repeatable assembly, ensuring consistent results across versions. For inspiration on complex builds and advanced print techniques, don’t miss the 3D printed RC helicopter resource, which showcases sophisticated rotary-wing experimental RC aircraft innovations.

Engage with the RC community to learn practical tips such as incorporating field-repairable joins, magnet-mounted hatches for easy access, and modular component swaps. Maintaining a detailed log of your flights, noting changes and results, is invaluable for guiding iterative design improvements and refining your custom-built models.

Conclusion: the joy of printing, building, and flying

Reflecting on the journey of transforming a simple sketch into a 3D printed RC fuselage that actually takes to the skies is truly rewarding. The process—from design, print, assemble, to fine-tune—teaches invaluable lessons in patience, iteration, and problem-solving. Each step in RC aircraft building brings its own challenges and discoveries, reinforcing the power of creativity and iteration in making DIY RC planes that not only look good but perform well.

- Design: Sketching and refining your concept with careful planning.

- Print: Watching your digital model come to life layer by layer.

- Assemble: Fitting parts together and ensuring a precise build.

- Tune: Adjusting controls and balancing for optimal flight.

The exhilaration when your radio controlled airplane finally lifts off is unmatched—a milestone that marks both achievement and the start of new possibilities. I encourage you to share your builds, remix designs, and embrace continuous experimentation. Whether you’re crafting intricate aerobats or simple, paper-inspired trainers, every flight hones your skills and brings you closer to perfection.

With thoughtful planning and a handful of test flights, your first 3D printed RC plane will definitely soar, and each subsequent model will fly even better. So take the leap, tinker boldly, and keep your passion for RC aircraft building soaring high!

Frequently Asked Questions

- Can you 3D print an entire RC plane?

Yes—many builders 3D print fuselages, wings, and control surfaces. Hardware like carbon spars, screws, servos, motor, ESC, receiver, and battery are still non-printed. Lightweight filaments (e.g., LW-PLA) and smart part segmentation make fully printed airframes practical. - What is the best material for a 3D printed RC aircraft?

Use LW-PLA for ultra-light skins and wings, standard PLA or PETG for non-sun-exposed or tougher parts, and ABS/ASA if you need heat resistance and have an enclosure. Most beginners succeed with a PLA + LW-PLA mix. - How much does it cost to make a 3D printed RC plane?

Rough estimate: $40–$90 in filament, $60–$150 for motor/ESC/servos/receiver, and $20–$60 for batteries and hardware. Total ranges from about $120 to $300+, excluding the printer you already own. - What software can I use to design RC planes for 3D printing?

Fusion 360, SolidWorks, and FreeCAD for parametric modeling; TinkerCAD for quick learning; plus slicing software like Cura, PrusaSlicer, or SuperSlicer for print preparation. - How do you make a 3D printed RC plane actually fly?

Design for correct wing loading, print light but strong (proper orientation and sparse infill), assemble accurately, set the center of gravity, choose and balance the right prop, and perform staged flight testing with trim and rate adjustments. - How durable are 3D printed aircraft compared to balsa or foam planes?

Printed planes can be stiff and precise but are often more brittle than EPP/EPO foam and heavier than balsa when overbuilt. With LW-PLA skins, carbon reinforcement, and smart design, durability becomes comparable for normal flying while staying field-repairable.