Mastering Model Airplane Gas Engines: A Guide to Long Flight Times and Authentic Sound

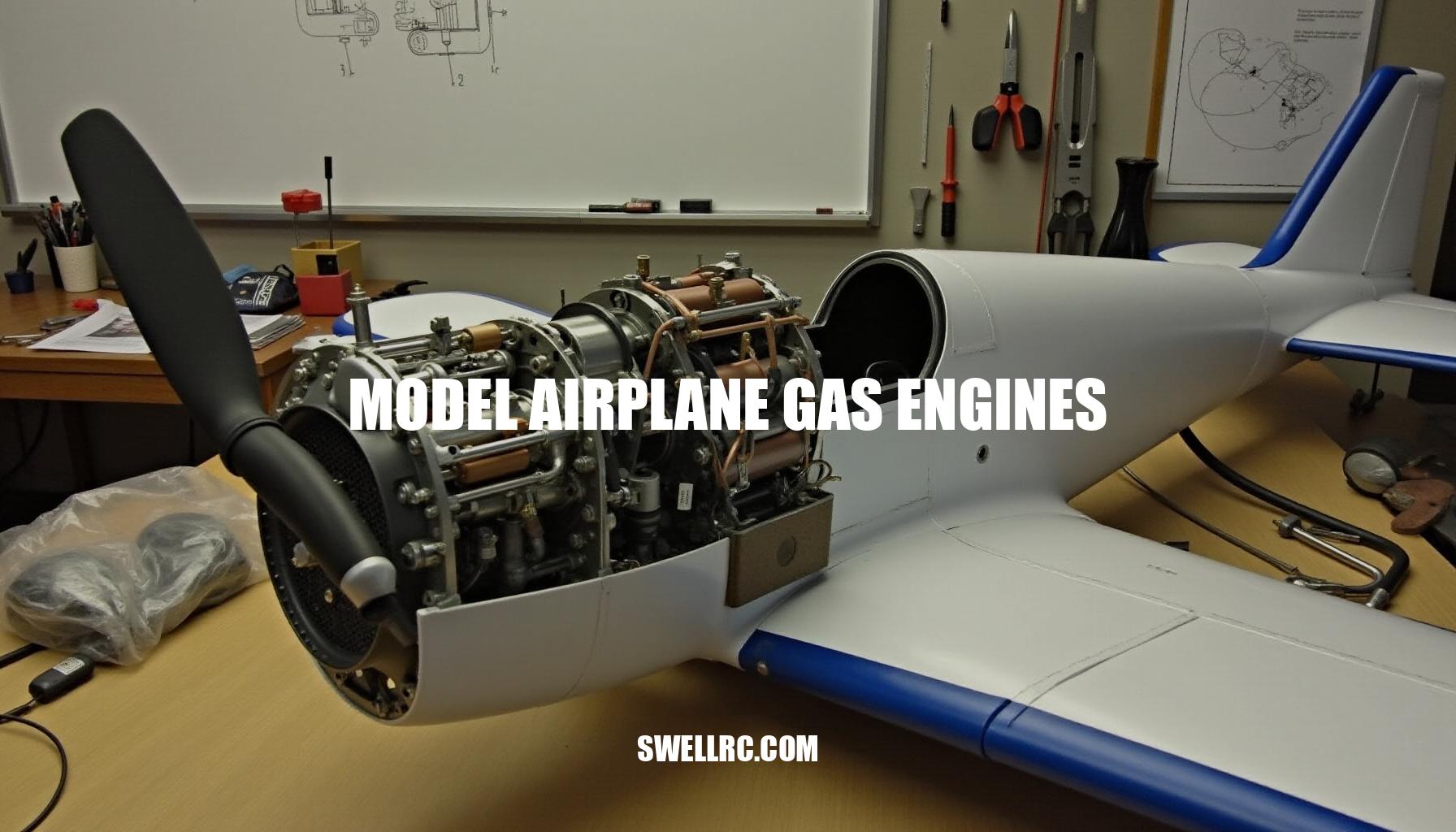

The first time a big-scale gasser thundered down our club runway, I felt it in my chest before I saw the plane. The prop wash smelled faintly of gasoline, the exhaust note was crisp, and the torque pulled that warbird into the sky with a kind of authority I hadn’t felt from electric or nitro alternatives. That flight sent me down a rabbit hole—bench tests, fuel experiments, prop swaps—until I finally understood what makes model airplane gas engines so compelling: realism, endurance, and consistent power.

For enthusiasts looking to dive into the world of gas-powered RC planes, understanding the mechanics behind RC airplane motors is essential. This guide will walk you through how these remote control aircraft engines operate, the differences between 2-stroke and 4-stroke designs, and crucial considerations on how to choose a gas engine for your RC plane based on displacement and performance. Additionally, you’ll gain insights into the maintenance and tuning habits favored by expert hobby aircraft mechanics to keep these engines running smoothly and reliably.

Whether you’re a seasoned pilot or a newcomer, start with a comprehensive overview of RC model airplane engines at this resource to fully understand your options and make an informed choice for your next build.

Understanding Model Airplane Gas Engines—What Really Drives These Machines

At heart, a model airplane gas engine is a tiny internal combustion machine that converts fuel energy into propeller thrust with wonderful mechanical theater. Air and fuel mix in the carburetor, the piston compresses the charge, and a spark plug—fired by an electronic ignition—ignites it. The expanding gases push the piston down, rotate the crankshaft, and spin the prop.

Key parts you’ll get familiar with include:

- Carburetor (mixture control and throttle)

- Reed or rotary valve (on some designs)

- Cylinder, piston, and rings (compression and sealing)

- Crankcase (lubrication and pumping)

- CDI ignition with hall sensor (precise spark timing)

- Muffler or tuned pipe (noise and scavenging)

Compared with other RC airplane engines (see a category overview at SwellRC), gasoline power trades a bit of weight for easier fueling, clean operation, long flight times, and lower cost per minute than nitro. Versus electric, gas brings the visceral sound and torque curve many scale pilots love, plus refuel-and-fly convenience.

Two classic architectures dominate: 2-stroke and 4-stroke. 2-stroke gasoline RC engines are lighter and generally make more power per cc, while 4-stroke model airplane engines (more on them here) offer a deeper, scale-like exhaust note, strong midrange torque, and efficient fuel burn.

If you want a deeper dive into the category of gasoline-powered RC engines, this hub is a good reference: Gasoline-Powered RC Engines.

| Feature | 2-Stroke Engines | 4-Stroke Engines |

|---|---|---|

| Weight | Lighter | Heavier |

| Power Output (per cc) | Higher | Lower |

| Torque and Thrust | Good torque, bursts of power | Stronger midrange torque, smoother thrust |

| Fuel Economy | Less efficient | More efficient |

| Sound | Sharper, higher-pitched tone | Deeper, scale-like exhaust note |

| Maintenance | Generally simpler | More complex, requires regular valve adjustments |

Performance, Power, and Efficiency—Choosing the Right Engine for Your Aircraft

Picking the right gas engine for your RC plane starts with understanding engine displacement for RC planes, measured in cubic centimeters (cc). Think of cc as your torque budget: a higher cc usually supports a larger propeller and a heavier airframe, thereby enhancing thrust and endurance. From my practical logs, here’s a rough guide that matches engine displacement with typical prop ranges, plane wingspan, and flight styles:

| Engine Displacement (cc) | Typical Prop Range (inches) | Plane Wingspan (inches) | Flight Style |

|---|---|---|---|

| 10–15 cc | 60–70 | Sport Models | Trainer, Beginner-Friendly |

| 20–30 cc | 70–85 | Warbirds, Aerobats | Sport, 3D |

| 35–60 cc | 80–100 | IMAC, Big-Scale | Competition, Scale |

| 70–120 cc (twins) | 100–120 | Giants | Scale, Heavy Lift |

Heavier or draggy airframes like biplanes and warbirds benefit from choosing the next size engine up to maximize power-to-weight ratio and maintain flight efficiency. When tuning RC gas engines, keep in mind that beginner-friendly engines aim for easy starts, forgiving needle valves, and smooth idling, while sport and 3D pilots prioritize crisp throttle response and optimal power density. Competition setups focus on maximizing power-to-weight with precise ignition mapping and propeller matching.

For real-world examples of airframes paired effectively with gas engines, check out this resource: Best Gas-Powered RC Planes. Brand-wise, I highly recommend OS for excellent reliability (OS Model Airplane Engines), while DLE and EME offer strong value choices.

In my testing, the recipe that consistently delivers outstanding performance is to use the manufacturer’s recommended oil ratio (often 25:1–40:1 with high-quality synthetic oil), carefully balance your propeller to reduce vibration, start the tuning slightly rich, and then fine-tune for a clean transition between throttle positions. For example, swapping from a 19×8 to a 20×8 prop can lower RPM but add thrust—ideal for enhanced 3D hover authority. Additionally, a small advance in ignition timing can sharpen throttle response; however, it’s important to keep an eye on engine temperatures and avoid detonation.

If you’re wondering which model airplane gas engine offers best power efficiency, focusing on these aspects—engine displacement matching your aircraft, quality tuning, and trusted brands—will ensure an optimized balance of thrust, endurance, and reliability.

Mastering Maintenance, Tuning, and Longevity

Gas engines reward consistent habits when it comes to engine maintenance and performance. For optimal results, follow a proper break-in routine: run the engine slightly rich for the first few tanks, vary the throttle to avoid steady full-power operation, and allow the engine to cool between heat cycles. Using fresh premium gasoline with the manufacturer-specified oil ratio is crucial, and installing a felt clunk or filter helps keep the fuel system clean; also ensure all fuel lines are alcohol and gasoline resistant.

Spark plug care is equally important: routinely check the plug gap, keep a spare CM6 or NGK plug on-hand, and inspect the ignition battery before each flying session. When it comes to carburetor tuning, set the low-speed (L) needle for a smooth, crisp transition off idle, and adjust the high-speed (H) needle to achieve the best peak RPM with a slight rich backoff, which helps maintain safe engine temperatures.

After flying, perform a thorough post-flight inspection by wiping off any fuel residue, checking all mount bolts, inspecting the prop hub and muffler screws, and ensuring proper ignition lead routing. Store your model airplane in a dry environment and follow storage tips such as draining the carburetor or running the engine dry and capping vent lines to prevent moisture ingress.

| Checklist Category | Key Actions |

|---|---|

| Break-in | Use correct oil ratio, keep rich needles, vary throttle, allow heat cycles |

| Tuning Flow | Set idle needle, fine-tune midrange, confirm wide-open throttle (WOT), re-check idle settings |

| Post-flight Inspection | Check mounts, ignition lead routing, muffler screws, wipe residue |

| Storage Tips | Drain or run engine dry, cap vent lines, store in dry location |

For beginners seeking how to maintain a model airplane gas engine, a buyer’s introduction to the category is available at https://www.swellrc.com/rc-plane-gas-engine/. For comprehensive insights into different engine types and compatibility, check out this tuning RC gas engines and maintenance guide: https://www.swellrc.com/model-airplane-engines/.

As a field anecdote highlights, troubleshooting midrange stutters during long uplines could reveal unexpected issues; in one case, a pinhole in the fuel line upstream of the carb caused aeration under sustained load, not needle settings. Keeping an eye on all aspects of your model’s fuel delivery, ignition, and tuning will ensure smooth, reliable performance every flight.

Alternative Power: When Nitro or Jet Engines Steal the Show

I love gas-powered RC planes for their economy, torque, and realism, making them a favorite among enthusiasts debating are gas model airplane engines better than electric options. However, I still keep nitro and turbines in my fleet for specific moods and flying styles. Nitro engines are prized for their razor-sharp throttle response and distinctive two-stroke scream, along with simpler onboard systems—just a glow plug and a fuel tank.

The tradeoff comes with higher fuel costs and more residue buildup, demanding regular maintenance. On the other hand, jets—whether turbines or electric ducted fans (EDF)—offer a completely different thrill: blistering speed, an authentic whoosh sound, and a scale jet presence that truly turns heads. But they require the most care, carry higher costs, and need field support tailored for turbine engines.

If you’re curious about the nuances between nitro vs gas engines or seeking an in-depth nitro engine guide and a hobby jet engine comparison, it’s helpful to summarize key attributes. Below is a quick comparison table highlighting the primary characteristics of gas, nitro, and jet engines, focusing on throttle response and maintenance among other aspects.

| Engine Type | Fuel Economy & Flight Time | Throttle Response | Maintenance & Setup | Ideal Usage |

|---|---|---|---|---|

| Gas | Economical fuel, supports long flights | Smooth torque, realistic engine sound | Slightly heavier engine, moderate upkeep | Perfect for big aerobats and warbirds |

| Nitro | Higher fuel cost, shorter flight times | Instant throttle, razor-sharp response | Requires frequent cleaning, simpler systems | Great for smaller aerobats & classic glow models |

| Jet (Turbine/EDF) | Fuel intensive, highest operational cost | Unmatched speed & authentic jet sound | Complex systems, extensive field support needed | For experienced pilots & turbine-approved fields |

Ultimately, choosing between gas-powered RC planes, nitro engines, or hobby jet engines depends on your budget, maintenance willingness, and flying preferences. Each offers distinct advantages in throttle response and maintenance demands that cater to different scales and piloting styles—making the world of RC planes exciting and diverse.

Conclusion: What I Learned—and Why Gas Engines Still Rule the RC Skies

After months of test stands, prop swaps, and headset recordings, my takeaway is simple: model airplane gas engines are the sweet spot for big-air authority and authentic flight vibes. They deliver the gasoline RC engines benefits of combining long flight times with a muscular, believable sound that truly enhances the flying experience.

Mastering engine tuning and longevity through proper fueling, tuning, and diligent post-flight checks ensures remarkable reliability for long flights. Whether you’re choosing a gas engine for your RC plane for the first time or refining a giant-scale build, embracing curiosity is key:

- Talk to clubmates experienced in gasser setups

- Study flight logs for tuning insights

- Celebrate every incremental gain — smoother idles, cleaner transition, and stronger climbs

The journey from the first sputter to the perfect tune is half the enjoyment. And when your plane finally lifts off on a wave of torque, you’ll understand why gas-powered engines continue to hold sway as a top choice in the RC flying hobby inspiration community.

| Key Aspect | Benefit |

|---|---|

| Long Flight Times | Enjoy extended sorties without frequent refueling |

| Authentic Sound | Experience powerful, believable engine noise for immersive flight |

| Engine Tuning | Enhances performance and extends engine longevity |

| Reliability | Consistent performance over long flights |

Frequently Asked Questions

- What is the difference between gas and nitro model airplane engines?

Gas engines use gasoline/oil mix with electronic spark ignition (CDI), offering lower running cost, longer flight times, and a deeper sound. Nitro (glow) engines use methanol/nitromethane/castor or synthetic oil with a glow plug, providing lighter setups and very crisp throttle but higher fuel costs and more residue. - Are model airplane gas engines reliable for long flights?

Yes—when properly tuned and maintained. Use fresh fuel at the recommended oil ratio, ensure good filtration, set needles slightly rich at WOT, confirm ignition battery health, and inspect mounts and muffler hardware. Many pilots log 15–30 minute flights routinely on gas. - How do I break in a new RC gas engine properly?

Run a quality oil mix at the manufacturer’s ratio, start with rich needles, use short heat cycles, vary throttle, avoid extended full-throttle runs early on, and retune after a few tanks as the engine seats. - What size gas engine do I need for my model plane?

Match displacement to weight and wingspan: roughly 10–15cc for 60–70 in sport models, 20–30cc for 70–85 in warbirds/aerobats, 35–60cc for 80–100 in giants, and 70–120cc twins for 100–120 in airframes. Biplanes and draggy models often need one size up. - How do 4-stroke RC airplane engines perform compared to 2-stroke engines?

4-strokes offer a deeper, scale-like sound, strong midrange torque, and good efficiency at a slight weight and complexity penalty. 2-strokes are lighter and usually produce more peak power per cc with simpler maintenance. - How do you tune a model airplane gas engine for top performance?

Warm the engine, set idle speed, adjust the low-speed needle for a crisp transition, then tune the high-speed for peak RPM and back off slightly rich. Verify in-flight with long uplines, monitor temps, and re-check idle after landing. - Which brands make the best model airplane gas engines?

OS is renowned for refinement and reliability; DLE and EME offer strong value and wide parts availability; DA (Desert Aircraft) is a top-tier choice for competition-level performance and support. Always match the brand’s strengths to your airframe and budget.