Ultimate Guide to RC Model Airplane Engines

RC model airplanes have been a popular hobby for decades, providing enthusiasts with the opportunity to fly miniaturized planes. One of the key components that determine the performance and power of an RC airplane is its engine. There are three main types of engines for RC model airplanes, namely glow engines, gas engines, and electric motors. Glow engines are powered by a blend of methanol, nitromethane, and oil. Gas engines run on gasoline and oil mixtures. Electric motors are powered by rechargeable batteries and offer the most convenient option. Each engine type has its own advantages and disadvantages, which should be taken into consideration when selecting an engine.

Engine Types for RC Model Airplanes

RC model airplanes have multiple types of engines that vary in performance, efficiency, and power. Below are the types of engines used in RC model airplanes:

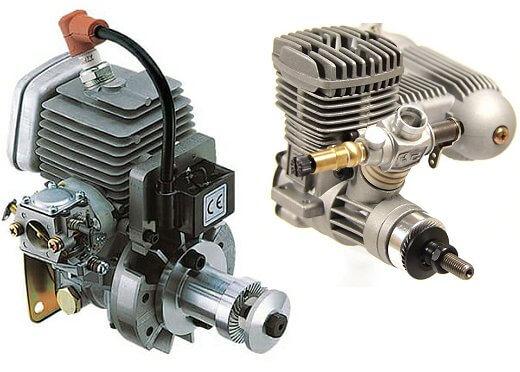

- Glow engines: Glow engines gained popularity during the early age of model aviation. They are powered by a blend of methanol, nitromethane, and oil. Glow engines have a simple design, provide sufficient power, and are more affordable than other engine types. However, they require more tuning and maintenance than other engine types, and the fuel they use can leave residue that can damage the engine over time.

- Gas engines: Gas engines run on gasoline and oil mixture, making them more fuel-efficient than glow engines. They offer more power and longer flight times, making them suitable for larger airplanes. Gas engines are also easier to start than glow engines. However, they are more expensive than glow engines and require more specialized knowledge to maintain.

- Electric motors: Electric motors use rechargeable batteries as their power source and offer the most convenient option. They are environmentally friendly, produce less noise, and require minimal maintenance. They provide instant power, making them suitable for smaller airplanes. However, they are generally less powerful than the other two engine types, and battery life limits flight time.

If you’re looking to purchase an RC airplane engine, there are many websites and retail stores that offer a wide selection of engines and parts. Be sure to consider your flying experience, airplane size, and performance requirements before making a purchase. Some popular brands for RC Model Airplane Engines includes E-flite and O.S. Engines.

What are some popular brands for RC model airplane engines?

Some popular brands for RC model airplane engines are Saito, Evolution, OS Engines, and DLE Engines.

Key components of an RC model airplane engineRole of each componentImportance of maintenance and replacement

An RC model airplane engine consists of several key components that work together to generate the necessary power for flight. These components include:

- Carburetor: Regulates the flow of the fuel/air mixture into the engine

- Crankshaft: Converts the reciprocating motion of the piston to rotary motion

- Piston: Compresses the fuel/air mixture and transfers the energy to the crankshaft

- Spark plug: Ignites the fuel/air mixture inside the engine

- Muffler: Reduces engine noise

Proper maintenance and replacement of engine components is essential for keeping the engine running smoothly and reliably. Over time, components can wear out or become damaged, compromising engine performance. Regular maintenance tasks should include cleaning, oiling, and checking for damage or wear on engine components. Replacement of worn-out components should be done promptly to prevent further damage to the engine. If you are unsure about how to replace or maintain engine components, there are many online resources and instructional videos available to help you.

What are some regular maintenance tasks for RC model airplane engines?

Some regular maintenance tasks for RC model airplane engines include checking and replacing spark plugs, cleaning and adjusting the carburetor, changing the oil, and checking for any leaks or damage to the engine.

Key Considerations for RC Model Airplane Engine Size

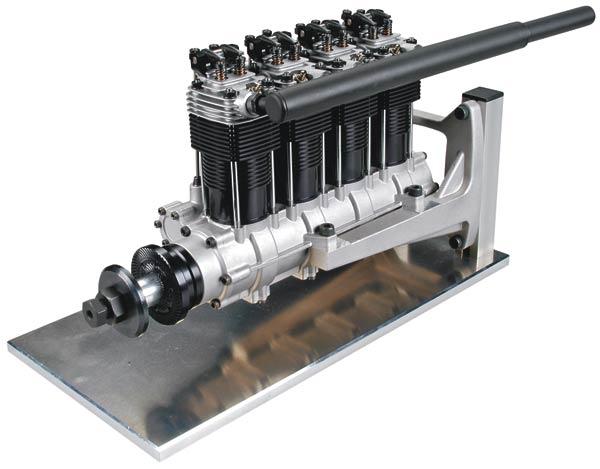

The size and displacement of an RC model airplane engine also play a crucial role in determining the airplane’s flight performance. Engine size is typically measured in cubic inches or millimeters, and larger engines generally generate more power. Some key factors to consider when selecting an engine size include the airplane’s weight and wingspan, as well as the type of flying you will be doing. Some common engine sizes and their associated power outputs include:

– 0.20 to 0.45 cubic inches – suitable for small airplanes weighing up to 4 pounds

– 0.60 to 1.20 cubic inches – capable of powering planes weighing up to 12 pounds or more

– 2-stroke engines – capable of producing higher power output and RPMs compared to 4-stroke engines

– 4-stroke engines – known for their smooth, quiet operation but typically generate less power than 2-stroke engines

When selecting an engine size, it’s important to carefully consider the airplane’s weight, wingspan, and intended use, as well as the power needs of the various components such as the propeller and servos. Various online retailers and hobby websites like Horizon Hobby and Tower Hobbies offer a wide range of engine options to suit various budgets and preferences.

What factors should be considered when selecting an engine size for an RC model airplane?

The factors that should be considered when selecting an engine size for an RC model airplane are the weight and size of the plane, the desired speed and flight time, the type of flying (aerobatic or scale), and the pilot’s skill level and preferences.

Effective RC Model Airplane Engine Maintenance and Troubleshooting

Proper maintenance of an RC model airplane engine is essential for maintaining its performance and longevity. Here are some basic engine maintenance tips to keep in mind:

-Regularly clean the engine using an air compressor or a soft-bristled brush and some warm, soapy water

-Oil the engine’s moving parts and bearings to keep them lubricated and prevent rusting

-Check for wear and tear on the engine’s components, including the carburetor, piston, and connecting rod, and replace any damaged parts

-Check the engine’s fuel lines for signs of wear or blockages, and replace them as needed

-Adjust the engine’s tuning settings (such as the needle valve and glow plug) to ensure optimal performance and fuel efficiency

Despite proper maintenance practices, RC model airplane engines can still experience problems from time to time. Some common engine problems and their solutions include:

-Fouled spark plugs – replace with new ones

-Clogged fuel lines – clean or replace the lines

-Overheating – reduce the engine’s fuel mixture or adjust the engine settings

-Compression loss – check the engine’s piston and cylinder for wear or damage, and repair or replace as necessary

Various online retailers like Amazon and hobby websites such as RC Universe offer a variety of engine maintenance products and tools, from oils and lubricants to replacement parts and cleaning supplies. Consulting online forums and communities can also help you troubleshoot engine issues and receive advice from experienced enthusiasts.

What are some common engine problems that can occur with RC model airplane engines despite proper maintenance practices?

Common engine problems that can occur with RC model airplane engines despite proper maintenance practices include carburetor issues, spark plug fouling, fuel line clogs, and overheating.

RC model airplane engines are complex mechanisms that require proper maintenance and care to keep functioning correctly. By following the basic maintenance tips outlined above, and identifying and addressing problems as they arise, it’s possible to keep an engine running smoothly for many flights to come.

It’s also important to keep in mind that, while maintenance can forestall issues, all engines will eventually reach the end of their useful lifespan. When that time comes, it’s important to replace them promptly to avoid airplane accidents or crashes. Additionally, rather than just discarding old engines, it’s a good idea to recycle them or donate them to hobby shops or other enthusiasts who can use them for spare parts.

In conclusion, RC model airplane engines are a crucial component in the performance and dependability of an RC airplane. Keeping these engines in good working order requires attention to basic maintenance practices and addressing issues as they arise. Remembering to replace worn-out or damaged components, and recycle or donate old engines, can also help ensure the safety of other hobbyists and prolong the lifespan of these fun and exciting toys. Therefore, always ensure regular check-ups, proper maintenance, and keeping your engine in peak condition is the key to a successful RC model airplane experience.