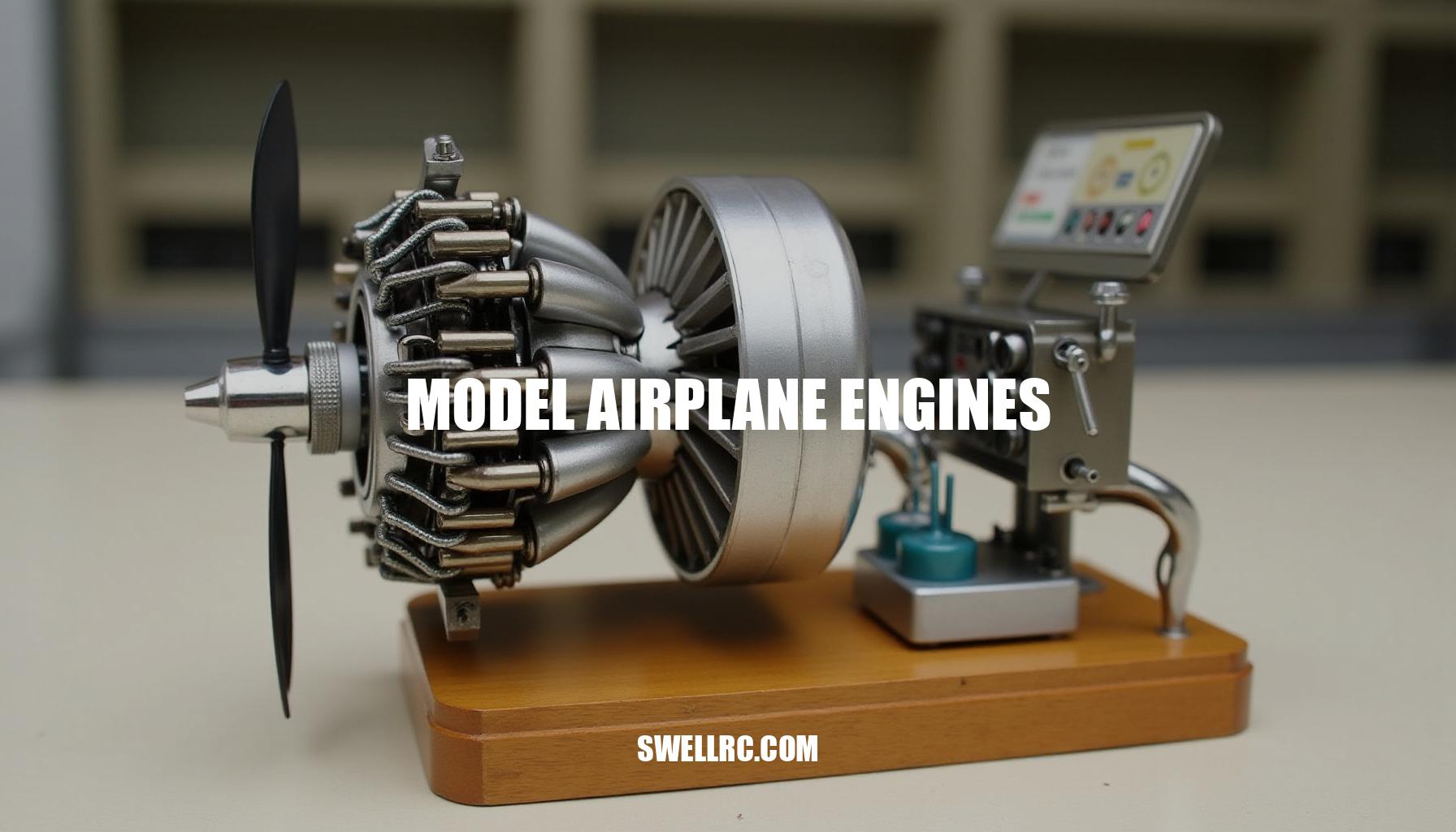

The Ultimate Guide to Model Airplane Engines

There’s a unique thrill I always feel when swapping out engines on the same RC airplane—watching an airframe transform from the gentle purr of a docile trainer to the razor-sharp snap of a needle-thin aerobatic beast. For me, model airplane engines aren’t just hobby engines; they’re a captivating obsession where craftsmanship, physics, and patience converge in tiny powerplants that bring radio control planes to life. This journey has taken me deep into the world of model aircraft motors—from classic nitro (glow) and gas engines to the sleek efficiency of electric setups and even the roaring excitement of miniature jet propulsion systems.

Along the way, I’ve also discovered a passionate subculture dedicated to vintage restorations, preserving the legacy of aviation’s early days. In this article, I’ll share clear explanations, hands-on tips, buying guidance, and hard-won engine tuning lessons to help you fly farther and fix faster, whether you’re searching for the best model airplane engine for beginners or looking to optimize your setup like a pro. Whether you’re just starting your radio control planes adventure or are a seasoned enthusiast craving test-proven insights, there’s something here to fuel your passion for all things model propulsion systems.

A Brief History of Model Airplane Engines — From Hand-Tuned Wonders to Jet Thrills

The journey of model airplane engines is a fascinating saga of nostalgia, innovation, and craftsmanship that mirrors the evolution of aviation itself. From the earliest days of vintage model aircraft engines, enthusiasts marveled at the intricate hand-fitted parts and the ritualistic needle-valve tuning required by compression-ignition (diesel) and glow engines. These early powerplants demanded patience and skill, with their rich, oily exhaust marking a signature presence at flying fields.

As technology progressed, the rise of nitro glow power from the 1960s brought an accessible burst of speed and that unmistakable castor-oil haze lingering in the air. Nitro RC engines offered hobbyists a thrilling balance of power and portability, fueling a golden era of radio-controlled flight and creating a strong community bound by shared passion and mechanical artistry.

The subsequent era welcomed the gasoline giants, where larger models benefited from reliable, economical fuel and impressive big-prop torque. These gas-powered engines carved a niche for scale enthusiasts who craved endurance and realism, pushing the boundaries of what model aircraft could achieve in size and capability.

The transformative electric revolution introduced brushless motors and LiPo batteries, democratizing power and precision while keeping the skies clean. Electric RC motors brought quieter, more environmentally friendly flights, and made the hobby more accessible to newcomers and seasoned pilots alike.

Not to be outdone, the leap to micro-turbines and kerosene jets marked a pinnacle of miniaturization and realism, allowing modelers to experience full-scale sound and speed in miniature form. These mini jet engines embody the fusion of craftsmanship and cutting-edge engineering, thrilling pilots with unparalleled authenticity.

On a personal note, handling a rescued barn-find engine from a bygone era was a humbling experience. The aged metal and worn engravings spoke volumes of countless hours in past skies. Restoring it to a smooth idle, hearing its steady hum once more—it was a profound connection to the legacy of vintage model aircraft engines and the pioneers who set these trends in motion.

For collectors and enthusiasts eager to delve deeper into this rich history, the vintage community offers a treasure trove of curated finds and rare powerplants that capture the spirit of bygone decades. Exploring gems available at https://www.swellrc.com/vintage-model-aircraft-engines-for-sale/ unveils stories etched in metal and fuel, perfect for those yearning to blend craftsmanship with nostalgia.

| Era | Typical Fuels | Ignition Types | Notable Innovations | Lessons for Today’s Builders |

|---|---|---|---|---|

| Pre-1960 | Diesel (Compression-Ignition), Early Glow Fuel | Compression Ignition, Glow Plug | Hand-Fitted Parts, Needle-Valve Tuning | Importance of Precision Craftsmanship & Mechanical Understanding |

| 1960–1990 | Nitro Glow Fuel (Methanol Mix) | Glow Plug | High-Performance Nitro Engines, Castor-Oil Exhaust Haze | Balancing Power & Accessibility; Community-Enriched Innovation |

| 1990–2010 | Gasoline | Spark Ignition | Large-Scale Reliable Engines, Economy, Big-Prop Torque | Scaling Up for Endurance & Realism |

| 2010–Today | Electric (LiPo Batteries), Kerosene (Micro-Turbines) | Brushless Electric, Jet Ignition | Brushless Motors, Micro Turbines, Eco-Friendly Flight | Precision, Clean Power & Advanced Miniaturization |

This evolution, richly layered with tales of ingenuity and dedication, continues to inspire current builders. Whether it’s the smell of vintage fuel or the quiet precision of an electric radio control plane, each engine tells a story—a legacy of craftsmanship that fuels not only models but the passion of generations.

Breaking Down the Types: Gas, Nitro, Electric & Jet Engines Explained

Exploring the world of model propulsion systems opens a thrilling array of engine types, each bringing unique characteristics and challenges to the skies. Let’s dive into the major varieties, mixing firsthand impressions with technical insights to help you discern the differences and ignite your interest in upgrading or experimenting with new powerplants.

Gas Engines

Flying a gas-powered engine offers a sensation of steady torque coupled with remarkably long flight durations that few other types rival. Their forgiving throttle response lets pilots confidently manage climbs and cruisers alike. These engines truly shine in large-scale warbirds, aerobatics, and tow planes, where endurance and torque make a tangible difference.

Owning a gas engine means dealing with ignition modules that simplify starts and running a fuel premix helping to balance oil and petrol for reliability and economy. In my tests, gas engines delivered excellent fuel efficiency with fewer refueling stops during marathons in the sky. Curious pilots can explore popular setups and detailed reviews at SwellRC’s gas engines collection.

Nitro (Glow) Engines

There’s something visceral about firing up a nitro RC engine—the crisp throttle snappiness, the classic combustion sound, and the nostalgic hint of a nitromethane-methanol blend lingering in the air. Perfect for sport flyers and smaller aerobats, these engines reward pilots who enjoy the tactile art of tuning needle valves and tweaking glow plugs for optimal performance.

The fuel mix demands precision, balancing nitromethane concentration to get that sweet spot between power and smoothness. During warm-up runs, I appreciated how subtle adjustments translate directly into on-air performance nuances. Prospective buyers should check the diverse options and tuning tips at SwellRC’s nitro engines page.

4-Stroke Engines

The 4-stroke RC engine captivates with its scale-like exhaust rumble and superior fuel economy, providing a strong midrange that is less jarring than its 2-stroke cousins. Ideal for scale models emphasizing realism and for pilots who prefer economy without sacrificing character.

Maintenance-wise, these engines demand more care—valve adjustments and oil changes contrast with the simpler upkeep of typical 2-stroke RC engines. However, the nuanced sound and smooth power delivery make the effort worthwhile. For those weighing these differences, explore examples with full specs at SwellRC’s 4-stroke engines.

Electric Power Systems

Many beginners gravitate towards electric RC motors because they offer a mess-free experience, instant startups, and highly precise throttle control. The core components—a brushless motor, ESC (Electronic Speed Controller), LiPo battery, and a carefully matched propeller to current draw—combine to deliver consistent, quiet, and clean flights.

Sizing your setup depends on the aircraft type: trainers benefit from moderate thrust and longer endurance, gliders require efficient power-to-weight ratios, and 3D ships demand high burst power and rapid throttle response. The simplicity of electric systems makes them widely accessible but also invites enthusiasts to experiment with tuning and battery technology.

Jet Turbines

If you crave the adrenaline of true turbine thrust, jet turbines bring a thrilling experience rarely matched by other engines. Spool-up whines, visible heat shimmer, and blistering thrust transform your RC model into a flying marvel. Usually reserved for experienced pilots, these engines link the progression from EDF (Electric Ducted Fan) systems to authentic turbojet power.

Operating a model jet engine requires knowledge of jet fuel handling, careful start sequences, and rigorous safety protocols. Airframe selection is critical since the robust thrust and heat output demand sturdy construction. For enthusiasts ready to explore, detailed overviews, hobby turbine models, and showcases of the largest RC jet engines can be found at Model Jet Engine overview, Hobby Jet Engine category, and Largest RC Jet Engine gallery.

Quick Pros-and-Cons Overview

| Engine Type | Cost | Maintenance | Noise | Power Density | Learning Curve |

|---|---|---|---|---|---|

| Gas-Powered Engines | Moderate | Moderate (ignition & fuel mixing) | Moderate | High torque, good flight endurance | Moderate |

| Nitro RC Engines | Low to Moderate | High (fuel tuning, needle valves) | High (classic combustion) | Good burst power | High (field tuning required) |

| 4-Stroke Engines | High | High (valve adjustments, oil maintenance) | Moderate (scale-like) | Lower rpm, smooth midrange | Moderate to High |

| Electric RC Motors | Variable (battery & ESC costs) | Low (battery care) | Low | High thrust-to-weight | Low |

| Model Jet / Hobby Jet Engines | Very High | High (fuel handling, safety) | Very High (turbine roar) | Extreme thrust | Very High |

Whether you seek the raw authenticity of a gas-powered engine, the intoxicating nostalgia of nitro, the realism of 4-stroke operations, the clean simplicity of electric RC motors, or the breathtaking power of a hobby jet engine, understanding these distinctions empowers you to tailor your flight experience and embrace new adventures in model aviation.

Inside the Mechanics — How Model Engines Deliver Real Power

Imagine you’re in your garage, curious about the tiny powerhouses driving model aircraft—the engines and motors that turn your hobby into thrilling flight. Let’s break down the basics of combustion engines and electric RC motors in a way that clicks, even if you’re just starting out with engine tuning.

First, think of a combustion engine as a carefully orchestrated dance of air and fuel. It starts by mixing air and fuel (the air–fuel mix) that gets compressed, ignited, and unleashed to push a piston—the power stroke. Think of 2-stroke engines like a quick two-step dance where fresh air-fuel mix grabs the stage as exhaust clears out simultaneously (called scavenging)—it’s fast and simple but less controlled.

In contrast, 4-stroke engines perform a four-part ballet: intake, compression, power, and exhaust strokes, thanks to valve timing that opens and closes valves like precise doorways managing the flow. It’s like comparing a fast shuffle to a carefully choreographed ballet.

Electric motors inside model aircraft motors use magnetic magic. Imagine the stator as a set of magnets arranged in a circle and the rotor as the spinning dancer attracted and repelled by those magnets in sequence. This sequence is managed by an Electronic Speed Controller (ESC) that times the magnetic pulses perfectly, creating smooth electromagnetic torque.

Change the battery voltage or the load—say a bigger propeller—and the RPM (rotations per minute) shifts, like the dancer adjusting pace to the music.

Let’s make some important terms simple:

- Displacement: The total volume inside the cylinders, essentially the ‘engine size’—bigger displacement means more air-fuel mixture and more power.

- Compression ratio: How tightly the air-fuel mix is squeezed before ignition—higher ratios mean more power but require precise tuning.

- Timing: When exactly the spark or electrical pulse happens—think of it as the conductor’s cue.

- Throttle response: How quickly the engine or motor reacts to your commands—snappy throttle means more precise control.

- Power-to-weight: A ratio showing performance efficiency—more power with less weight gives faster acceleration and climb.

- Prop pitch: The ‘bite’ of the propeller—higher pitch moves more air per rotation but requires more power.

Visualizing this, picture side-by-side cutaways: on one side, a nitro or gas engine’s crankcase shows air flowing through crankcase ports pumping fresh fuel-air mix; on the other, a brushless motor’s stator and rotor illustrate magnetic fields pushing the rotor around. A flow arrow diagram highlights how in a 2-stroke, fresh mix and exhaust flow simultaneously during port openings, while in a 4-stroke, valves open and close methodically in sequence.

As a practical example, troubleshooting a rough idle once led me to find a tiny air leak at the carburetor base. Sealing that tiny gap suddenly made throttle pickup crisp and reliable—showing how intimate fixes can improve overall engine tuning and throttle response.

Important to remember: handle fuel carefully with proper ventilation, keep fingers clear of spinning propellers, and always use a secure test-stand to safely run engines or motors during tuning.

By blending these insights, your first garage tinker session becomes less mystifying—building your confidence and trust in the mechanics behind your model aircraft’s heart, whether it’s a nimble 2-stroke or a precise brushless electric motor.

Choosing the Perfect Engine — Matching Power with Purpose

Choosing the best model airplane engine for beginners or seasoned pilots hinges on asking yourself some mission-critical questions: What type of airframe are you flying? Is your style more relaxed or aerobatic? How tolerant are you to noise?

Do your flying field rules impose restrictions? What’s your budget? And finally, how much maintenance are you prepared to handle?

To help guide your decision, consider this practical decision table for selecting RC airplane engines based on your aircraft category and skill level:

| Aircraft Type | Recommended Engine Types |

|---|---|

| Trainers and Park Flyers | Electric or small nitro engines |

| Sport and Aerobatic Planes | Nitro or gas engines (depending on size) |

| Large-Scale Warbirds and Tow Planes | Gasoline engines |

| Gliders | Electric motors |

| True Scale Jets | Turbine engines |

Power-to-weight is a key metric to keep in mind: for electric setups, target roughly 100-150 watts per pound to ensure lively performance. For combustion engines, focus on displacement and propeller diameter, aiming for a healthy margin that equips your plane for clean takeoffs and impressive vertical maneuvers. Keep your aircraft’s all-up weight in mind to size your engine correctly.

Practical constraints also factor into your choice. Consider fuel availability in your area, muffler requirements under your club rules (which often limit noise), and the accessibility of spare parts and support. Budgeting smartly means balancing these factors with the joy of flying.

For an all-in-one experience, explore SwellRC’s curated selection of engines perfectly suited for every style and skill level. Visit https://www.swellrc.com/rc-airplane-engines/ to browse the full range of RC airplane engines and unlock the perfect powerplant for your airplane.

Don’t be afraid to experiment—whether it’s the exhilarating moment you find “that perfect roar” of a gas engine or the blissful whisper of a quiet electric setup perfectly matched to your field’s noise limits. Each engine type offers unique thrills and challenges to enhance your flying journey.

Before you start shopping, gather your key inputs for a quick power calculator: your aircraft’s all-up weight (AUW), wing area, and the level of performance you desire. These metrics will help pinpoint the best model airplane engine for beginners or advanced pilots alike, guiding you toward that perfect balance of thrust, efficiency, and fun.

Maintenance, Tuning & Longevity Secrets the Pros Swear By

Maintaining and fine-tuning your RC engine isn’t just a hobby—it’s an essential craft that leads to smoother throttle response, enhanced performance, and prolonged engine longevity. Here’s a hands-on guide packed with real-world maintenance habits and tuning tricks, based on experience and aimed at helping you master your RC setup.

Routine Checklist:

- Pre-flight: Always start with a clunk line check to ensure fuel delivery. Verify carburetor linkages move freely, inspect glow plug or ignition lead integrity, and confirm prop nut torque is secure to prevent in-run loosening.

- After-run: Clean your engine meticulously after each session to prevent grime build-up. For nitro engines, apply after-run oil to protect against corrosion. Don’t forget to inspect and clean air filters regularly to maintain optimal airflow.

- Seasonal Storage: For combustion engines, fogging cylinders helps prevent rust and corrosion. Electric RCs benefit from storing LiPo batteries at recommended storage voltages. Always store components in dry, dust-free environments to avoid damage.

Tuning Fundamentals:

- Nitro Engines: Begin by setting the high-speed needle at its peak RPM, then richen it slightly for a safe air-fuel mix. Adjust the idle and low-speed needles to achieve a clean transition without hesitation or burble.

- Gas Engines: Start with baseline needle settings as per the manual. Fine-tune gradually to attain crisp throttle response without any lean sag, ensuring effective combustion and smooth acceleration.

- Electric Motors: Choose a propeller that allows headroom for current draw, preventing overheating. Verify ESC timing is properly set, and ensure adequate cooling to extend electronic component life.

Troubleshooting Quick-Fix Table:

| Issue | Likely Causes | Remedies |

|---|---|---|

| Starting Difficulty | Flooded engine, weak glow plug, clogged fuel line | Clear excess fuel, replace glow plug, check & clean fuel line |

| Overheating | Lean mixture, blocked cooling fins, excessive prop size | Rich mixture, clean fins, use smaller prop |

| Inconsistent Idle | Dirty carb, air leaks, incorrect needle setting | Clean carb, check seals, adjust needles |

| Midrange Burble | Lean low-speed needle, dirty air filter | Rich low-speed needle, clean or replace filter |

| RF Interference | Poor receiver antenna placement, inadequate shielding | Reposition antenna, use shielding or ferrite loads |

Personal Tip Bank: During break-in, keep your engine slightly rich and run at varied throttle to seat components properly. Always balance props before use to reduce vibrations. Invest in quality fuel and never underestimate how a fresh glow plug cured my mysterious top-end miss—often, small upgrades lead to big gains.

Benefits of Disciplined Maintenance: Applying systematic maintenance and precise engine tuning results in a noticeably smoother throttle response, extended engine life, and fewer frustrating dead-sticks during operation.

Safety Reminders: Always use a starter with proper restraint to avoid injury. Wear eye protection, and practice fire safety rigorously when handling fuel or LiPo batteries.

The Joy of the Hobby — What Keeps Us Hooked

There is a serene magic in the calm of a well-tuned idle—a gentle hum that resonates with every enthusiast’s heart. This sound doesn’t just represent mechanics; it embodies craftsmanship refined through patience and passion. Beyond the individual effort lies a vibrant community, where the communal cheer after a maiden flight echoes the joy shared among friends and family, each celebrating a new milestone in the lifelong journey of model airplane engines.

The art of working with hobby engines is a delicate dance between technical prowess and aesthetic finesse. From hand-fitting linkages with meticulous care to polishing spinners until they gleam, and maintaining spotless fuel systems, each step showcases the fusion of artistry and engineering. These tasks transform simple model aircraft motors into living masterpieces, carrying the legacy of generations who found wonder in tiny revolutions per minute.

Picture a Saturday at the field:

- Swapping props under the warm sun, each model telling its own story.

- Comparing notes on tuning secrets, an exchange of knowledge fueled by shared enthusiasm.

- Tuning engines side by side, laughter mingling with the soft roar of spinning blades.

This vignette reflects the heart of the hobby—a place where nostalgia meets innovation. Whether restoring a vintage gem with the care of a historian or witnessing the awe-inspiring spool-up of a first turbine, enthusiasts bridge eras through their dedication and love for these machines.

We invite you to join this enduring tradition: share your own builds, fixes, and favorite engine sounds. Together, let’s celebrate the community that cherishes the emotional depth and timeless spirit of model airplane engines.

Conclusion — Lifting Off Into the Future

As we conclude this exciting journey through the world of model airplane engine technology, it’s inspiring to reflect on how far we’ve come—from the intricate art of hand-tuned classics to the power of high-thrust turbines and the elegance of whisper-quiet electrics. At the core, the essence of choosing the perfect engine remains: aligning your mission, budget, and, most importantly, the joy per minute from every flight.

Looking ahead, the future of RC engines is brimming with innovation. Imagine AI tuning algorithms guiding carburetor adjustments for peak performance, smart ignition timing systems that adapt in real-time, the rise of hybrid models combining electric and combustion power, and the adoption of greener, sustainable fuels enhancing model propulsion systems. These advancements promise to elevate our flying experiences to new heights.

On a personal note, I’m thrilled to embark on my next test project, exploring some of these cutting-edge technologies firsthand. I warmly invite each of you to continue experimenting, learning, and flying together—because the sky is not the limit but just the beginning.

Before your next build, I encourage you to revisit our detailed sections featuring comprehensive buying and setup checklists to ensure your aircraft is optimized for success.

- Recap: Hand-tuned classics, high-thrust turbines, whisper-quiet electrics

- Core principle: Match mission, budget, and joy per minute

- Future innovations: AI tuning, smart ignition, hybrid-electric boost, greener fuels

- Next steps: Keep exploring with SwellRC’s resources and community support

Frequently Asked Questions

- What are the different types of model airplane engines?

The main types are gas (gasoline), nitro glow (methanol/nitro/castor), electric (brushless motor + ESC + LiPo), and jet turbines (kerosene micro-turbines). Each offers distinct trade-offs in cost, maintenance, noise, and performance. - How does a model airplane engine work?

Combustion engines mix air and fuel, compress it, ignite it (glow element or spark), and convert the expanding gases into crankshaft rotation that spins a prop. Electric systems use a battery-powered ESC to drive a brushless motor’s magnetic fields, turning the shaft with instant, precise control. - Which is better for RC planes — gas, nitro, or electric engines?

It depends on your goals. Electric is clean, quiet, and beginner-friendly. Nitro is visceral, compact, and great for sport flying. Gas offers long flight times and torque for larger models. Turbines deliver the ultimate realism and speed but require experience and budget. - How do you maintain and clean a model airplane engine?

Inspect fuel lines and linkages pre-flight, keep filters clean, wipe off residue, oil nitro engines after flying, balance props, and store engines dry. Follow manuals for needle settings and use quality fuel. For electrics, maintain good cooling and store LiPos at 3.7–3.85 V per cell. - What’s the most powerful model airplane engine ever made?

In practical RC use, large kerosene turbines in the 300–400 N thrust class (around 65–90 lbf) are among the most powerful. For prop-driven models, big gasoline engines in the 300–400 cc range can produce tens of horsepower for giant-scale aircraft. - How to choose the right engine size for my RC airplane?

Match power to airframe and flying style: use watts-per-pound for electric (typically 80–200+ W/lb) and manufacturer recommendations for displacement and prop size on combustion engines. Add headroom for verticals and consider noise, field rules, and budget. - Are vintage model airplane engines still functional for flight?

Yes, if inspected and restored properly. Check bearings, compression, carburetion, and seals; run on appropriate fuel and use modern radio gear. Many pilots fly restored engines, while rare pieces are kept for display and collection.