Model Jet Engines: Design, Types, and Safety Tips

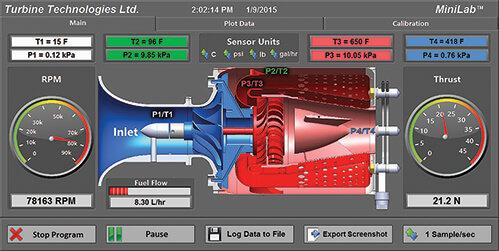

Model jet engines are small but powerful engines that are used to power model aircraft. They are incredibly popular among hobbyists due to their unique features and ability to replicate the sound and performance of real-life aircraft engines. These engines are specially designed to provide high thrust-to-weight ratios, generate high operating temperatures, and operate at high speeds. Unlike traditional gasoline engines, model jet engines do not have carburetors or spark plugs and rely on a specially formulated fuel to ignite and create a hot combustion gas that propels the aircraft forward. They come in two main types: turbojet and turbofan engines, each with their own set of design, operation, and performance characteristics. Despite their small size, model jet engines require precise machining, careful assembly, and proper maintenance to ensure safe and reliable performance.

Features and Varieties of Model Jet Engines

- The unique characteristics of model jet engines include:

- Small size, making them ideal for powering model aircraft

- High thrust-to-weight ratio, allowing them to generate a lot of power in proportion to their weight

- High operating temperatures, which are necessary for creating the combustion gas that propels the aircraft forward

- Ability to operate at high speeds, providing realistic performance for model aircraft

- Unlike traditional gasoline engines, model jet engines do not have:

- Carburetors or spark plugs

- They rely on specially formulated fuel to ignite and create the combustion gas that propels the aircraft forward

- Model jet engines come in two main types:

- Turbojet engines

- Simpler in design and provide a more realistic sound for model aircraft

- Turbofan engines

- More complex in design, but provide greater fuel efficiency and a higher thrust-to-weight ratio

What are the two main types of model jet engines?

The two main types of model jet engines are electric ducted fan (EDF) and turbine.

Small and simple: The power of a model jet engine lies in its size and design.

- Turbojet engines:

- Smaller in size and simpler in design than turbofans

- Great for aircraft models that require a realistic jet-like sound

- Typical thrust-to-weight ratio ranges from 2.5:1 to 5:1

- Turbofan engines:

- Larger and more complex than turbojets

- Greater fuel efficiency and thrust-to-weight ratio

- Used in large-scale model aircraft and some UAVs

- Typical thrust-to-weight ratio ranges from 5:1 to 10:1

When it comes to model jet engines, there are two main types: turbojet engines and turbofan engines. Turbojet engines are smaller and simpler in design than turbofans. They are great for model airplanes that require a realistic jet-like sound. The typical thrust-to-weight ratio for a turbojet engine ranges from 2.5:1 to 5:1.

On the other hand, turbofan engines are larger and more complex than turbojets. They offer greater fuel efficiency and thrust-to-weight ratio. These engines are typically used in large-scale model aircraft and some UAVs. The typical thrust-to-weight ratio for a turbofan engine ranges from 5:1 to 10:1.

What is the typical thrust-to-weight ratio range for a turbofan engine used in large-scale model aircraft and some UAVs?

The typical thrust-to-weight ratio range for a turbofan engine used in large-scale model aircraft and some UAVs is between 2:1 to 5:1.

Parts, Materials, and Assembly Process

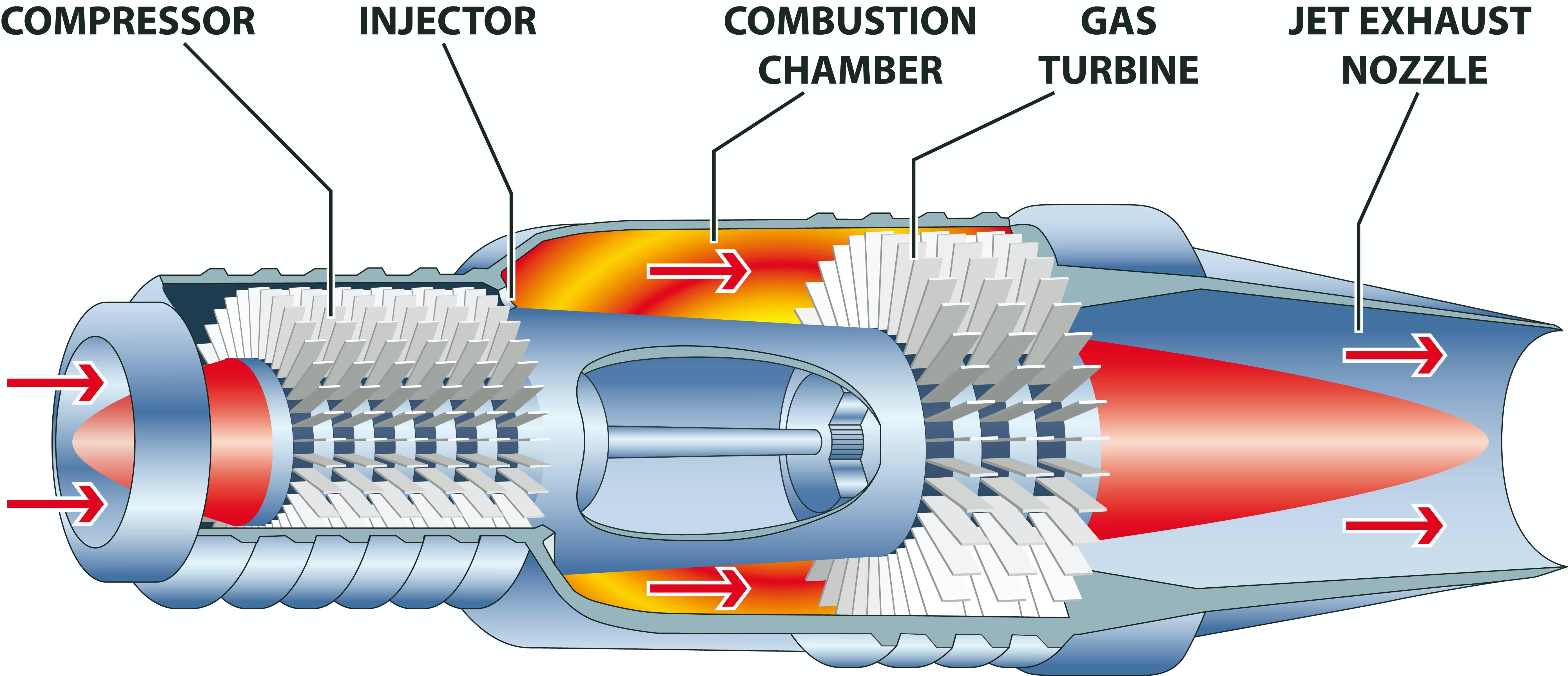

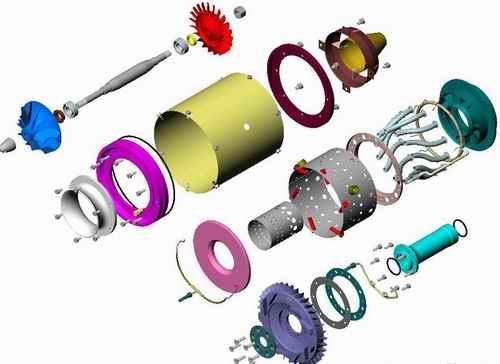

- Parts of a model jet engine:

- Compressor

- Burner

- Turbine

- Nozzle

- Materials used:

- Aluminum alloys for the compressor and turbine blades

- High-temperature metals and ceramics for the burner and nozzle

- Stainless steel for the shaft and bearings

- Assembly process:

- Parts are machined to precise tolerances using computer-controlled machines

- Parts are assembled with high-strength adhesives or with screws/nuts and bolts depending on the design

- The engine is tested for performance and safety

What materials are used to make the different parts of a model jet engine?

The different parts of a model jet engine can be made from a variety of materials such as aluminum alloys, titanium alloys, nickel alloys, composites, and ceramics.

Starting and Stopping Procedures.

- Fueling process:

- Model jet engines typically use kerosene-based fuels mixed with lubricating oil

- The fuel is poured into a tank or reservoir attached to the engine

- A fuel pump and delivery system inject fuel into the burner where it is ignited

- Starting and stopping procedures:

- Electric starter motors or compressed air starter systems are used to start the engine

- To stop the engine, the fuel supply is cut off and the engine is allowed to run until it stops

- Cleaning and maintenance:

- Engines should be cleaned after every use to remove dirt and debris that can clog the fuel injectors

- The engine should be disassembled periodically for inspection and cleaning of the parts

- Bearings and other moving parts should be lubricated regularly to prevent wear and damage

What are the recommended cleaning and maintenance procedures for model jet engines?

The recommended cleaning and maintenance procedures for model jet engines include checking for proper fuel mixture and oil levels before each use, cleaning the engine after each use with a soft brush and compressed air, checking for any leaks or damage, and storing the engine in a safe and dry place.

Important Safety Considerations

- Potential risks and safety considerations:

- Model jet engines operate at high temperatures and can pose a fire hazard if not used and maintained properly.

- Fuel leakage can also be dangerous if not addressed promptly and properly.

- The blades and other moving parts of the engine can cause injury if they come into contact with fingers or other parts of the body.

- It’s important to follow all safety precautions and guidelines provided by the manufacturer when using and maintaining model jet engines.

- Wear appropriate protective gear, such as gloves and eye protection, when operating these engines.

- Only use fuel and other components that are specifically designed for use with model jet engines.

What safety precautions should be followed when using and maintaining model jet engines?

Safety precautions when using and maintaining model jet engines include wearing proper protective clothing, handling fuel carefully, ensuring proper fuel storage, following manufacturer instructions for operation and maintenance, securing the jet engine properly, using a fire extinguisher nearby, and never allowing inexperienced users to operate the engine.

Conclusion

In conclusion, model jet engines are a popular and fascinating technology used by hobbyists and enthusiasts to power model aircraft. These small engines are designed and constructed to generate high thrust-to-weight ratios and operate at high temperatures. There are two main types of model jet engines, turbojet and turbofan, each with unique features and performance characteristics. When operating and maintaining these engines, safety must be a top priority, as they can pose risks such as fire hazards and injury from moving parts. However, with proper care and maintenance, model jet engines can provide reliable and efficient power for model aircraft.

If you’re interested in exploring more about model jet engines, there are many online resources available. Websites such as RC Universe and JetCat USA offer information on products, parts, and maintenance, as well as forums and communities where hobbyists can connect and share information and tips. As with any hobby or technology, it’s important to approach model jet engines with care and respect, but the potential for fun and exploration is well worth it.