Mastering RC Electric Motors: Understanding Kv, Voltage, and ESC Pairing

After noticing how different RC motors made my plane behave in completely new ways—smooth climbs with one setup, rocket-like launches with another—I fell down the rabbit hole of understanding RC electric motors. It’s wild how a palm-sized device can turn electrons into jaw-dropping speed, stump-pulling torque, and the personality of your RC car, boat, or airplane. From drift-tuned brushless cars to water-cooled boat screamers and efficient trainers in the sky, the motor choice shapes everything about your electric propulsion system.

If you’re curious about airplane-specific options, a quick browse of RC electric motors for airplanes shows just how diverse the choices really are. In this guide, we’ll break down how RC motors work, how to read specs like Kv and torque, and how to choose and optimize a setup that feels made for your model—without drowning in jargon or complexity. Whether you’re debating brushless vs brushed or diving into hobby motors with a personal experience in mind, understanding these fundamentals will power your journey into the electrifying world of RC airplanes, boats, and cars.

The Basics — How RC Electric Motors Work

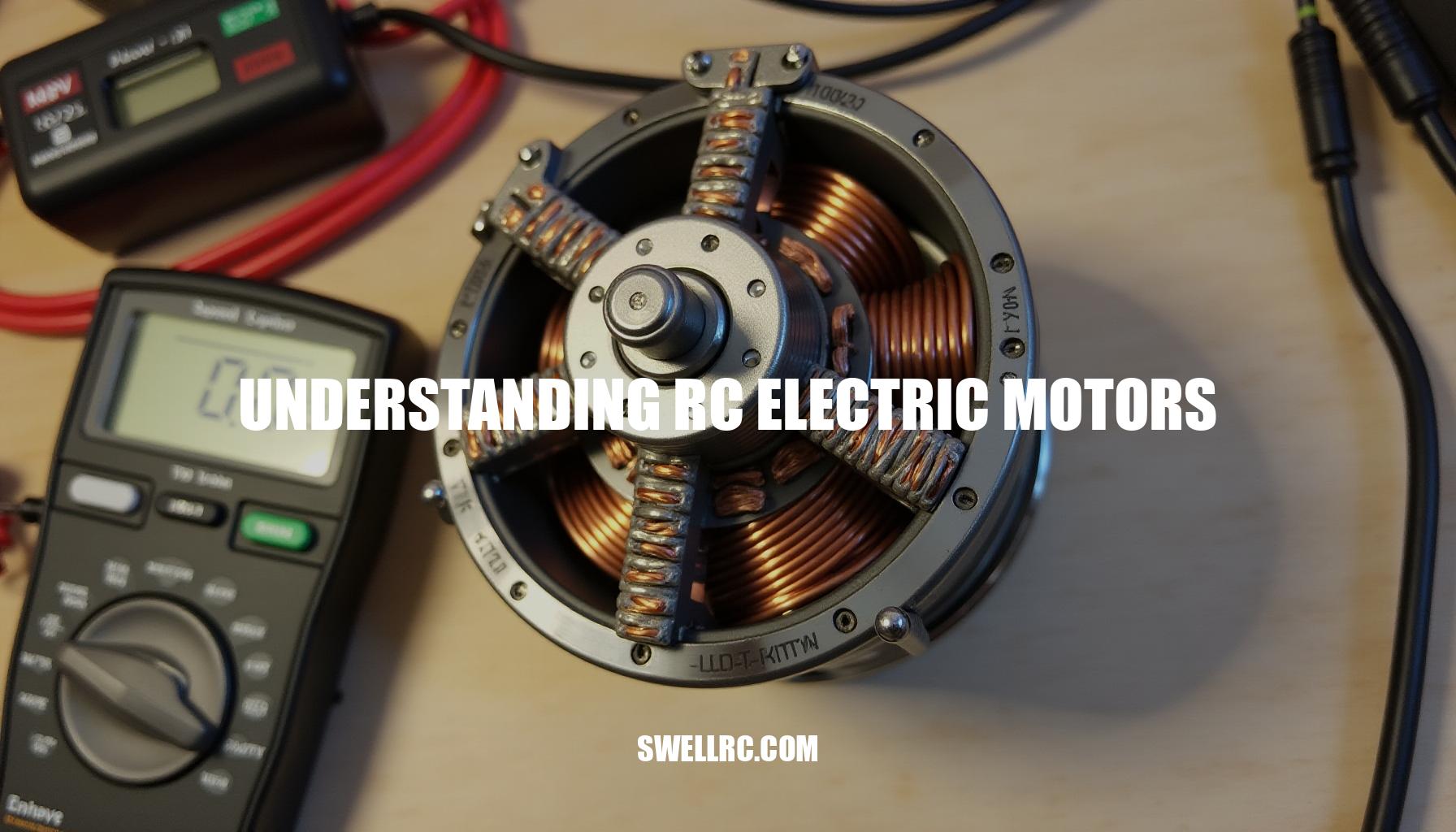

At their core, RC motors turn electrical energy into motion using electromagnetic induction: current flows through copper motor windings in the stator, creating a magnetic field that tugs on permanent magnets in the rotor. This interaction causes the motor to spin, generating thrust or wheel torque essential for RC vehicles. Understanding the differences between brushed vs brushless motors is key for enthusiasts looking to optimize performance.

In brushed motors, physical brushes mechanically switch current between windings, whereas in brushless motors, an electronic speed controller (ESC) handles this switching electronically. This makes brushless motors cleaner, faster, and more efficient. The Kv rating indicates how many revolutions per minute (RPM) a motor will spin per volt with no load, while the torque curve represents torque output variation with current; torque per amp is essentially the inverse relationship of Kv.

Additionally, core materials, magnet grade, and winding style (turns and wire gauge) significantly influence the torque curve and overall efficiency. For a broader primer comparing power systems including nitro or gas, see the basics of RC engines at https://www.swellrc.com/basics-rc-engines/.

I couldn’t believe how just swapping motor types rewired the entire feel of my car. Here’s a short comparison at a glance:

| Motor type | Commutation | Maintenance | Efficiency | Torque at low RPM | Best for | Cost |

|---|---|---|---|---|---|---|

| Brushed | Mechanical brushes/commutator | Higher (brush wear) | Moderate | Strong initial torque | Beginners, crawlers, budget builds | Lower |

| Brushless | Electronic via ESC (3‑phase) | Low | High | Scales with gearing/ESC timing | Performance, racers, planes/boats | Higher |

Power and Performance — The Heartbeat of RC Motion

Speed, torque, and efficiency form a delicate interplay influenced by voltage, current, Kv rating, and load conditions. Increasing voltage on a motor with the same Kv results in a higher RPM potential, while opting for a lower Kv at the same voltage yields greater torque per amp, highlighting the crucial balance between voltage and current. Power output, being the product of volts and amps, means that both the battery and ESC must have sufficient headroom to perform effectively.

The ESC integration plays the role of the conductor, skillfully modulating voltage through PWM and orchestrating phase sequencing in brushless motors to optimize performance.

From my hands-on experience with LiPo batteries and motors, a mini case study on a 1/10 buggy tested at 2S with a 3300Kv motor versus 3S with a 2200Kv motor—adjusting gearing to maintain similar top speed—revealed insightful outcomes. The 3S/2200Kv setup operated cooler, delivered stronger mid-range torque, and demonstrated better runtime due to reduced current draw for equivalent power. This underscores the importance of strategically tuning for efficiency and runtime optimization.

Key lessons for optimizing ESC and motor performance include:

- Gear for temps and terrain, not just speed: Selecting gear ratios that prevent overheating improves overall system reliability.

- Use LiPo packs with adequate C-rating: This avoids voltage sag, ensuring steady voltage and current delivery under load.

- Monitor ESC timing and motor load: Excessive propeller size or gear ratio can kill efficiency by increasing current draw.

- Keep motor temperatures below ~80–90°C: Overheating risks demagnetization and accelerates bearing wear, degrading performance.

- Add airflow or water-cooling (for boats): Cooling solutions help prevent overheating, especially during long stall conditions that strain the system.

By understanding the dynamics of Kv vs torque, ensuring proper ESC integration, managing power delivery from LiPo batteries, and emphasizing overheating prevention, you can transform RC setups from temperamental to trustworthy performers.

Choosing the Right Motor — Matching Power to Purpose

Picking the right motor for your RC vehicle becomes straightforward when you follow a comprehensive checklist designed to simplify motor sizing. First, consider the model weight and target power-to-weight ratio. This is fundamental in determining the amount of thrust or torque needed.

Second, identify your use case: whether it’s bursty acceleration for RC cars, steady thrust for RC airplanes, or continuous high-load operation for RC boats. Third, select the battery voltage you intend to run, as this affects motor performance directly. Fourth, choose the Kv range which must align with your gearing setup or propeller diameter and pitch, a crucial element in balancing torque vs speed.

Fifth, both the motor and ESC should have current capabilities exceeding the expected load to ensure durability and performance. Sixth, check the physical size, weight, and mounting options to ensure the motor fits your model. Finally, consider the cooling path, whether air or water, to prevent overheating during operation.

- Model weight and target power-to-weight ratio

- Use case: bursty acceleration (RC cars), steady thrust (RC airplanes), or continuous high-load (RC boats)

- Battery voltage selection

- Kv range fitting your gearing or prop size

- Current capability: motor and ESC exceeding expected load

- Physical size, weight, and mounting

- Cooling path: air or water cooling

For RC airplanes, start by examining the airframe weight and mission profile such as trainer, sport, 3D, or glider. This approach helps in understanding watts-per-pound requirements and proper prop selection. For a detailed guide, see how to size an electric motor for an RC airplane, which walks through motor sizing, wattage per pound, and proper ESC and battery pairing.

When choosing a motor for RC cars, take into account surface traction and gearing, which greatly influence load dynamics. Mapping the Kv rating to tire size, spur/pinion ratios, and track style ensures optimal torque vs speed balance and efficient power transmission. A thorough walkthrough on how to select brushless motors for RC cars offers detailed advice on motor sizing and gearing.

In the case of RC boats, the propeller acts like a gear in water, where diameter and pitch substantially affect current draw. Starting with conservative props and employing water-cooling systems is advised for sustained performance. Exploring RC boat motor insights and specialized electric outboard options can help match motor characteristics to hull type and speed goals effectively.

Trade-offs are inevitable: lower Kv with higher voltage generally delivers cooler, more efficient power, ideal for extended runs. Conversely, higher Kv motors may provide snappier response but require precise gearing or prop control to avoid overheating or damage. Balancing torque, speed, and efficiency is essential based on your terrain, water, or air environment.

Deeper Mechanics — Understanding the System Behind the Spin

A motor’s performance is truly dependent on the entire RC system surrounding it. When you operate your radio transmitter, it sends commands through a control link—most commonly using modern 2.4 GHz spread-spectrum technology, though legacy systems might still rely on 27MHz frequencies—to the receiver. The receiver interprets these commands into precise ESC signals, which manage throttle, timing, and current limits for the electronic speed controller (ESC).

This orchestrated process enables the motor to generate the required torque and RPM, which then powers the drivetrain or turns the propeller in aircraft setups. Ultimately, this sequence produces motion, delivering the necessary speed or thrust based on your control inputs. Here’s a simple flow illustrating this interaction:

- Stick input (TX)

- Receiver (RX)

- ESC (throttle command, timing, current limit)

- Motor (torque/RPM)

- Drivetrain or prop

- Motion (speed, thrust)

It’s fascinating how your fingers, combined with clever electronics and fundamental physics, seamlessly translate commands into pure movement within an RC system.

Common Mistakes and Optimization Tips

When it comes to optimizing your RC motor performance and avoiding common pitfalls, understanding a few critical mistakes can save you time and expense. Here are the top 5 RC motor mistakes I’ve made — so you don’t have to — focusing on key areas like overheating, ESC calibration, gearing, prop sizing, wiring best practices, LiPo C-rating, and temperature management:

- Over-gearing or over-propping: It may feel blisteringly fast on the bench, but once on the track or water, your motor overheats quickly. To fix this, step down the pinion size or reduce the prop diameter and pitch.

Always monitor your amp draw and temperatures closely to prevent damaging heat buildup.

- Mismatching Kv and voltage: Selecting a motor with sky-high Kv for your battery voltage results in RPMs you’ll never use and generates excess heat. Choose a motor Kv that matches your power source and gearing, aiming for the loaded RPM you need rather than the theoretical no-load RPM.

- Ignoring ESC limits: Many RC enthusiasts overlook their ESC’s continuous and burst current ratings, causing brownouts, cutoffs, or even fried FETs. Make sure your ESC’s ratings comfortably exceed your real-world current draw by at least 20–30% for reliable operation and better ESC calibration.

- Poor cooling and airflow: Motors sealed in bodies or hulls cook quickly without proper ventilation. Integrate vent holes, fans, or ducted airflow mechanisms.

For boats, reliable water-cooling jackets can make the difference between overheating and smooth operation.

- Sloppy wiring and solder joints: High resistance due to undersized wires, long runs, or poor solder joints translates to heat and power loss. Use appropriate gauge wires, keep wiring runs short, apply solid solder techniques, and secure your connectors carefully following wiring best practices.

For further optimization, consider these quick hits:

| Optimization Tip | Benefit |

|---|---|

| Calibrate your ESC throttle endpoints | Improves throttle response and prevents unnecessary heat spikes |

| Start at conservative gearing/prop sizes and incrementally increase | Allows for effective temperature management and prevents sudden overheating |

| Use quality LiPos with adequate C-rating and keep them balanced | Ensures stable power delivery and prevents voltage sag |

| Check bearings and alignments regularly | Reduces friction which is a major source of free heat |

| Log motor temperature, runtime, and speed during sessions | Provides data-driven guidance for tuning changes |

By addressing these key areas—overheating, appropriate ESC calibration, proper gearing and prop sizing, adherence to wiring best practices, selecting the right LiPo C-rating, and vigilant temperature management—you can significantly improve your RC motor’s reliability and performance.

Conclusion — Why Understanding Your Motor Changes Everything

Mastering motor mastery is the key to transforming random trial-and-error into intentional performance tuning for your RC electric motors. By understanding Kv and voltage like a detailed map, you can make informed choices that elevate your builds. Selecting an ESC pairing that perfectly complements your motor and setup ensures smooth and efficient power delivery.

To truly optimize performance, focus on gearing optimization or choosing the right props to keep temperatures in check, preventing overheating and prolonging the lifespan of your components.

Every meticulous tweak feels like unlocking a new level of control—whether that means boosting speed when needed, extending runtime for longer fun, or enhancing overall durability.

Here’s a quick checklist to guide your tuning process:

- Analyze your motor’s Kv and voltage ratings for compatibility

- Choose an ESC that matches your motor’s specifications

- Fine-tune gearing or prop size based on temperature and performance feedback

- Test and adjust settings to hit your desired balance of speed and endurance

- Document changes to perfect your setup over time

Embrace this journey of RC enjoyment by continuously exploring and testing. The more you understand about your motor and system, the more thrilling each run, sail, or flight becomes.

Frequently Asked Questions

- What exactly does an RC electric motor do?

It converts electrical energy from your battery into mechanical rotation. That rotation becomes wheel torque in cars, prop thrust in planes and boats, or shaft power in specialized setups—controlled by the ESC to match your throttle input. - What’s the difference between brushed and brushless RC motors?

Brushed motors use mechanical brushes to switch current, which makes them simple and inexpensive but less efficient and higher maintenance. Brushless motors use an ESC for electronic commutation, delivering higher efficiency, power density, and durability—ideal for performance builds. - How does an ESC control an RC motor?

The ESC regulates voltage and current to the motor using high‑frequency switching. In brushless systems it sequences three phases using back‑EMF (sensorless) or Hall sensors (sensored) to commutate the rotor, and it can add features like braking, timing advance, current limiting, and telemetry. - How do I size an electric motor for my RC airplane or boat?

For airplanes, start with model weight and mission to estimate watts‑per‑pound, then choose a motor/prop/ESC that meets the power target without overheating. For boats, size the motor to the hull type and prop load—begin conservatively, monitor current and temperature, and adjust prop diameter/pitch as needed. - Why do some RC cars use 27MHz signals?

27MHz is an older AM/FM radio band once common in RC. It’s more prone to interference and requires frequency crystals; most modern systems use 2.4 GHz spread‑spectrum for better range, reliability, and automatic channel management. - How can I prevent overheating in my RC motor setup?

Use appropriate gearing or prop sizing, ensure good airflow or water‑cooling, match Kv to your battery voltage, and pick an ESC with adequate current headroom. Monitor temps and avoid long stall conditions; high‑quality bearings and sound soldering also reduce wasted heat. - What affects the speed and torque of an RC motor?

Kv and battery voltage set the RPM ceiling, while motor size, winding design, and load (gearing or prop) determine torque and current draw. ESC timing, efficiency, and overall power‑to‑weight ratio also strongly influence acceleration and top speed.