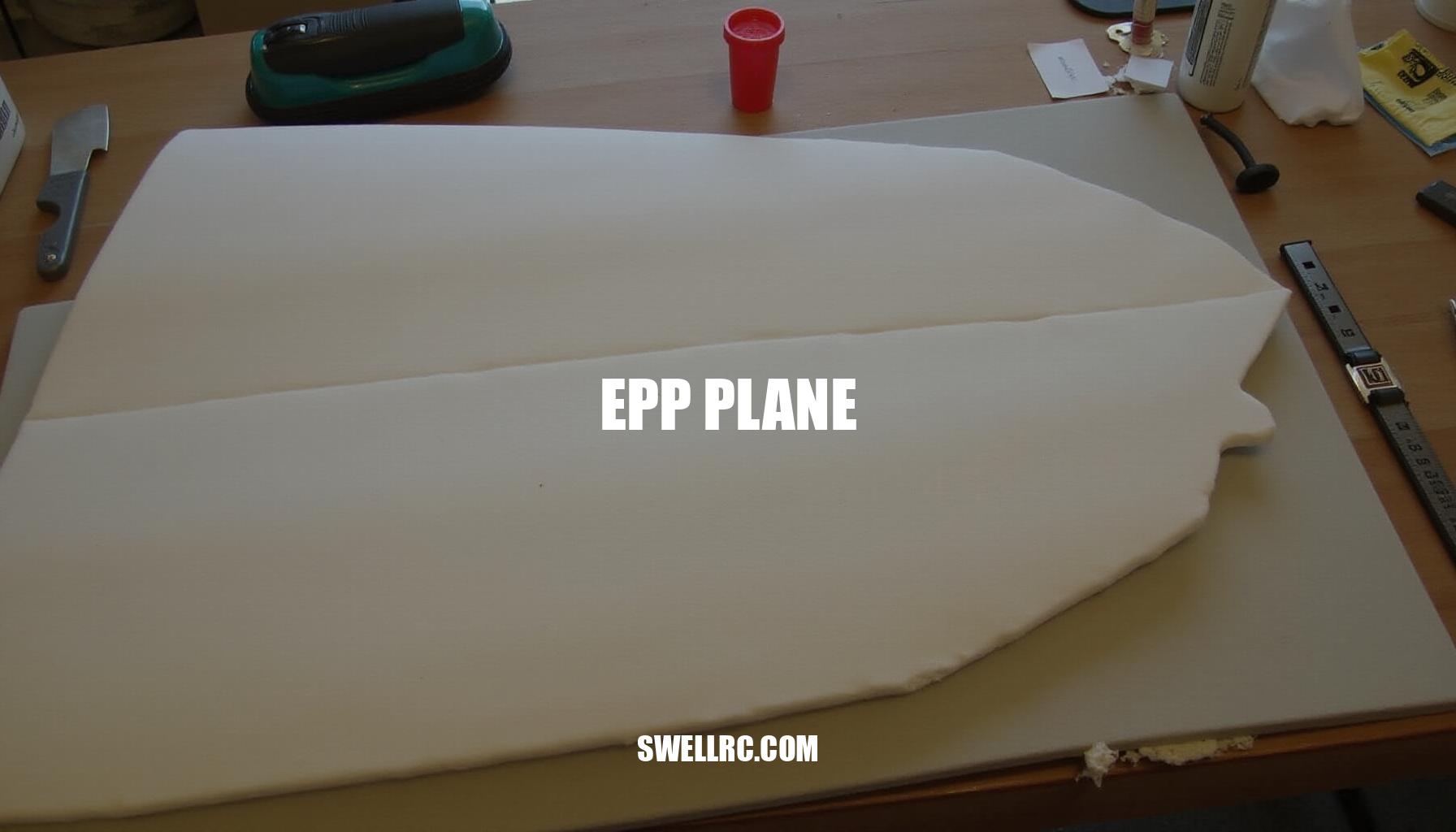

The Ultimate Guide to EPP Planes: Crash-Resistant RC Aircraft for Beginners

I didn’t expect to find this much difference in foam—until I cartwheeled a new model across a gravel field and it shrugged off the crash like it was nothing. That was my first EPP foam moment. It felt like unlocking a secret in the RC world: not all foams are created equal, and Expanded Polypropylene (EPP) plays by different rules.

EPP is a flexible, closed-cell foam with incredible “memory,” so it bends and springs back instead of cracking. If you’ve flown traditional foams that dent or snap, EPP’s resilience is honestly shocking. When exploring RC airplane materials, EPP stands out among foam plane types because of its ability to endure tough landings and maintain airframe integrity.

In model aircraft building, selecting a flexible foam airplane material like EPP can make a significant difference in durability and performance. Compared to other popular foams such as EPO and Depron, EPP offers superior toughness, making it ideal for remote control flight enthusiasts who push their planes through challenging maneuvers, from first flights to hardcore 3D practice and FPV expeditions. Understanding the unique properties of EPP foam not only enhances the flying experience but also broadens the possibilities in designing and customizing resilient RC airplanes.

Understanding EPP Foam – What Makes EPP Planes Practically Unbreakable?

Expanded Polypropylene (EPP) is a popular choice for RC hobby kits due to its uniquely light yet durable bead foam construction. Made from polypropylene spheres fused into a closed-cell lattice, EPP offers exceptional crash resistance by absorbing and rebounding energy instead of fracturing. Its foam density typically ranges between 20–40 kg/m³, striking the ideal balance of lightweight structure and high durability, making it the best material for RC planes designed to withstand the rigors of frequent flying.

This resilient property makes EPP especially suited for crash-resistant RC planes that must endure repeated landings, hard field operations, and even pilot errors like botched harriers. Pilots often turn to EPP for both indoor precision fliers such as F3P planes and outdoor 3D trainers which demand reliable performance without constant repairs. For instance, minor wingtip damage can often be repaired quickly: warming the foam gently and applying foam-safe glue can restore structural integrity, allowing the aircraft to return to flight without noticeable performance loss.

To better understand how EPP compares with other common materials like EPO and Depron, here’s a quick glance at weight, flexibility, and crash resistance attributes:

| Material | Weight | Flexibility | Crash Resistance |

|---|---|---|---|

| EPP (Expanded Polypropylene) | Low to Medium | High | Very High |

| EPO | Low to Medium | Medium | High |

| Depron | Low | Low | Low to Medium |

In summary, EPP’s unique combination of foam density, flexibility, and unmatched crash resistance establishes it as a cornerstone material in advanced RC hobby kits. Whether you’re flying precision indoor models or tough outdoor sport planes, EPP foam helps ensure your model withstands the challenges of active flying sessions with minimal damage and easy repairs.

EPP vs Other Foam Types – Why EPP Outsmarts EPO, Depron, and Traditional Foam

When considering popular foam materials in the RC plane community, understanding their distinct characteristics helps in choosing the right one for your project. EPP feels slightly rubbery and forgiving in hand, providing flexibility and excellent crash resistance for agile wings or slope bashers. EPO, on the other hand, is stiffer and more “plastic,” rewarding smooth piloting with cleaner surface finishes but offering less flexibility.

Depron stands out for its extreme lightness and crisp feel, making it ideal for indoor builds, though it is more brittle and less forgiving on impact.

Comparing EPO vs EPP and Depron vs EPP across key attributes reveals important trade-offs:

| Material | Flexibility | Cost | Ease of Repair | Weight | Surface Finish |

|---|---|---|---|---|---|

| EPP | Highly flexible and forgiving | Moderate | Excellent; foam-safe CA, UHU POR, warm water fixes | Light to moderate | Matte, less smooth compared to EPO |

| EPO | Stiffer, less forgiving | Moderate | Fair; needs careful gluing, harder to fix dents | Moderate | Smoother, semi-gloss finish |

| Depron | Light and crisp but brittle | Low | Poor; prone to cracking and difficult to repair | Very light | Matte, very thin foam |

In flight, a flexible foam airplane made from EPP excels at absorbing chatter and ground knocks, which is invaluable for pilots learning aerobatics or flying low and fast. Its ease of repair and crash resistance make it the favored choice for crash-prone platforms and experimental RC plane types. Conversely, EPO demands smoother control inputs to maintain its clean surfaces, while Depron’s ultralight nature favors indoor or gentle flying conditions requiring delicate handling.

Modern kits, such as the sleek Heewing F-01, demonstrate how combining tough foams like EPP with smart reinforcements can achieve both durability and performance in scale models.

EPP in the Real World – FPV: Endurance you can trust

When it comes to choosing the best material for FPV planes, EPP stands out as a top option, especially for those interested in a durable long-range FPV plane. EPP foam acts like a safety net during flights, providing exceptional tolerance against belly landings, rough terrain, and even occasional tip-stalls. This makes it highly suitable for pilots who want to extend their flying sessions without the constant fear of damage.

One key advantage of EPP is its ability to embed critical gear such as antennas, GPS systems, and VTX units securely within the frame.

This integration enhances both functionality and durability, minimizing the risk of sudden cracks or failures during flight. If you’re exploring crash-resistant RC planes, EPP-based models should definitely be on your shortlist.

For those looking to build or upgrade, exploring various RC hobby kits tailored for long-range flying can offer invaluable insights and inspiration. To dive deeper into the best platforms and ideas for your FPV adventures, be sure to check out the comprehensive long-range FPV picks and tips.

- Durability against impacts and rough landings

- Compatibility with embedded electronic gear

- Lightweight build for extended flight time

- Ideal for both beginners and seasoned pilots

| Feature | Description |

|---|---|

| Material | EPP Foam |

| Benefits | Crash resistance, flexibility, lightweight |

| Applications | Long-range FPV planes with embedded antennas, GPS, and VTX |

EPP in the Real World – Aerobatics: Pattern practice and indoor precision

EPP foam technology enables pilots to practice big-air pattern lines and aggressive 3D maneuvers with real forgiveness, making it an ideal choice for both indoors and outdoors flying. Indoors, the ultra-light EPP airframes of F3P RC planes float beautifully, enhancing control and precision. When flying outdoors, the addition of a bit of carbon and laminate stiffens the airframe for crisp snaps while maintaining the “bounce-back” safety net typical of a flexible foam airplane.

This unique combination results in more stick time, faster learning curves, and fewer repairs, which are crucial benefits for enthusiasts of F3A pattern planes and those looking to master an aerobatic RC plane.

EPP in the Real World – Utility and scale: Bush ops and twins

If you love multi-mission and short-field fun, EPP’s ruggedness truly shines. Ideal for utility RC planes, the material ensures your aircraft can handle bush flying, cargo drops, and STOL RC plane practice with carefree durability. The airframe’s resilience means it can take a thump without compromising performance, making it perfect for adventurous pilots.

For enthusiasts seeking scale RC planes with robust construction, consider workhorse-style inspirations like the Twin Otter RC plane.

Alternatively, the broader kit ecosystems such as Nexa RC planes offer a variety that combines durability with design flexibility.

When selecting your next model, keep in mind the importance of RC airplane materials. EPP provides an excellent balance of lightweight strength and shock resistance, making it a top choice for pilots who demand both performance and ruggedness.

EPP in the Real World – EDF and high-speed exceptions

EDF RC planes often use different materials to optimize performance and durability. While EPP vs EPO is a common debate among enthusiasts, understanding their impact on surface finish and stiffness is crucial, especially for a high-speed RC plane. EPP can efficiently handle EDF layouts due to its lightweight and flexible nature.

However, for high-speed airflow, a stiffer, smoother surface finish significantly improves aerodynamic efficiency.

Many pilots employ mixed-material constructions to balance these factors effectively:

- Using EPP cores combined with glass or laminate skins to enhance rigidity and surface smoothness.

- Switching to EPO or composite materials to achieve superior surface finishes and structural stiffness.

To further explore ducts and fans and understand how material choice affects EDF performance, refer to this comprehensive guide: What is EDF RC Plane?

The Experience – Flying an EPP Plane: The Feel and the Freedom

The first time I yanked a too-low knife-edge and pancaked in, I winced—then laughed. My RC flying experience instantly transformed. The EPP airframe bounced back effortlessly, allowing me to quickly check the control throws and launch again without hesitation.

This freedom changes how you fly: you try new lines, flirt with the wind, and keep experimenting with confidence.

In gusty conditions, the flexible foam airplane construction of the EPP material smooths out twitchiness, providing a more stable remote control flight. And when you tap a wingtip or nose, the beauty of a crash-resistant RC plane shines through—repairs take minutes, not weekends.

I’ve tested various ideas on platforms ranging from sport profiles to boutique builds. Brands like Esprit offer a great sandbox for experimenting with gear and setups, enhancing your overall flying enjoyment.

For those interested, check out their lineup here: Esprit RC Planes.

Buying Guide – Choosing Your First (or Next) EPP RC Model

When buying an EPP plane or selecting from various RC hobby kits, it’s essential to consider several critical factors to ensure optimal performance and enjoyment. Start by defining your flight style—whether it’s trainer, FPV cruiser, slope, 3D aerobatics, or pattern practice—which dictates design priorities. Next, evaluate wingspan and wing loading; longer wingspans combined with modest wing loading typically enhance stability and efficiency, ideal for both beginners and experienced pilots.

The choice of foam density plays a pivotal role; lighter foams are preferable for indoor or park flying, while denser or laminated materials are suited for increased speed and wind resistance. Selecting an appropriate power system—matching motor, propeller, or EDF to your plane’s thrust-to-weight ratio and intended missions—is crucial for achieving desired performance.

Additionally, incorporate a stiffness plan that may include carbon spars, laminate film, or strategically applied tape in high-stress areas to maintain structural integrity. Ensure your electronics bay accommodates FPV gear with easy service access and proper cooling.

Prepare for maintenance by having repair readiness supplies such as foam-safe CA, UHU POR glue, blenderm tape, spare propellers, and control horns. Finally, verify the availability of spare parts like wings, noses, and landing gear to extend the longevity of your model.

In summary, to select the best material for RC planes, especially if you’re a beginner RC plane enthusiast, pick a mission-oriented model, size it for your flying field and skill level, choose foam density and reinforcement tailored to your speed profile, validate power and CG margins, and stock up on repair supplies and spares before your maiden flight.

Conclusion – The Verdict: EPP Planes Are Built for the Brave

EPP turns crashes into lessons instead of losses. Its unique blend of lightweight EPP foam, flexibility, and repairability lets you fly harder, lower, and longer—without the fear tax. The RC community’s love for crash-resistant RC planes isn’t hype; it’s hard-won experience from countless saves and quick fixes. If you want more stick time, faster progression, and fewer heartbreaks in your RC hobby, an EPP plane is the smartest leap you can take.

When exploring foam plane types, EPP foam stands out for its durability and ease of repair, making it ideal for remote control flight enthusiasts who want to maximize fun and minimize downtime.

See you out there—pushing lines, laughing off bumps, and coming home with a fully intact airframe.

Frequently Asked Questions

- What is an EPP plane?

An EPP plane is an RC aircraft built from Expanded Polypropylene foam, a flexible, closed-cell material known for its exceptional impact resistance and “memory.” It bends and rebounds instead of cracking, making it ideal for training, aerobatics practice, slope soaring, and rugged FPV use. - Is EPP better than EPO for RC planes?

For crash durability and easy repairs, yes—EPP generally outperforms EPO. EPO is stiffer with smoother surfaces and can look cleaner at the field, which some pilots prefer for scale or speed. If you’re learning, experimenting, or flying rough, EPP is usually the safer bet. - How durable are EPP planes for beginners?

Very durable. EPP absorbs impacts from tip-stalls, cartwheels, and hard landings that would snap other foams. Most mishaps are fix-and-fly: a little foam-safe glue, tape, and you’re airborne again—great for building confidence. - Can I repair an EPP RC plane easily?

Yes. Foam-safe CA (with kicker), UHU POR, and flexible adhesives work well. Dents and warps often come out with warm water or gentle heat. Reinforce stress points with carbon spars or laminate, and use tape for quick field fixes. - What is the best foam for FPV planes?

For long-range and rugged FPV, EPP is often best due to its impact resistance and forgiving installation of antennas and electronics. If you need high speed and a smooth finish, EPO or composite skins may be preferable. - How light is EPP foam compared to Depron or EPO?

Typical hobby EPP is about 20–40 kg/m³, Depron sheets are commonly around 30–45 kg/m³, and EPO is often 35–60 kg/m³. EPP can be very light while staying resilient; Depron is light but brittle; EPO is heavier and stiffer with a smoother surface.