Demystifying DC Speed Controllers: How Does a DC Speed Controller Work?

Stepping into the fascinating world of technology, one can’t help but marvel at the intricate devices that power our lives. DC Speed Controllers are one such mesmerizing invention. They arose from a sheer necessity – our ever-growing need for precision and control. From the silent hum of a refrigerator to the roar of an electric car, managing the speed of DC motors has become a critical necessity. Imagine trying to use your blender without being able to adjust its speed; less than ideal, isn’t it? Similarly, any motor, be it in your car or computer fan, requires fine-tuning of speed. This is where our little maestro, the DC speed controller steps in. It’s akin to the conductor of an orchestra, perfectly coordinating the symphony of speed that our devices need to operate smoothly. It has a history as rich and varied as the countless machines it governs; dedicated researchers and tech enthusiasts pour over journals and studies, each trying to add their note to this technical concerto. So, buckle up as we delve deeper into the rhythm and melody of DC Speed Controllers.

How a DC Speed Controller Works

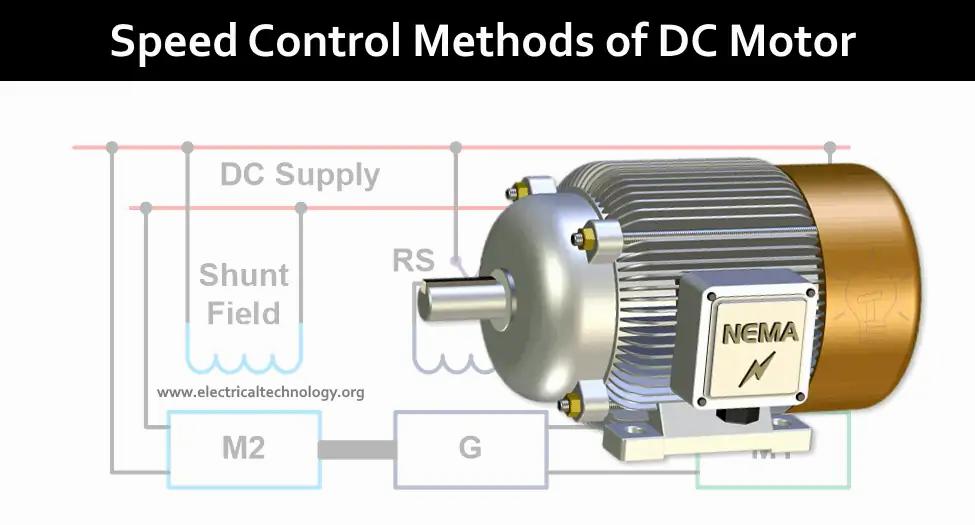

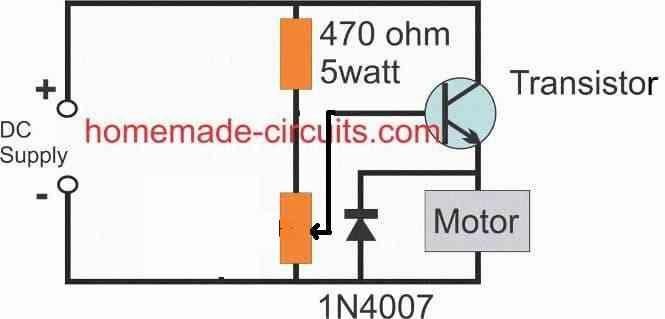

So, how does a DC speed controller work? Well, at its simplest, you can think of it as a traffic controller on a bustling highway. Its main job? To efficiently and strategically manage the flow of electric ‘traffic’ – in this case, the voltage – to a DC motor. But instead of using traffic signals, a DC speed controller employs certain techniques like changing voltage inputs and pulse width modulation to control motor speed.

Changing voltage inputs is akin to adjusting the speed limit on our hypothetical highway. Just like a higher speed limit allows cars to move faster, a higher voltage input makes the DC motor speed up. On the contrary, lowering the voltage slows the motor down, similar to how reducing the speed limit slows traffic.

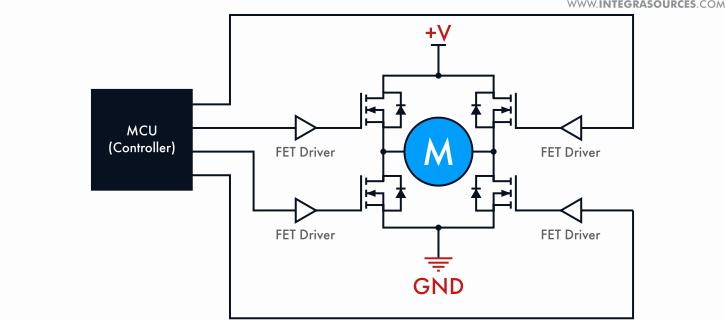

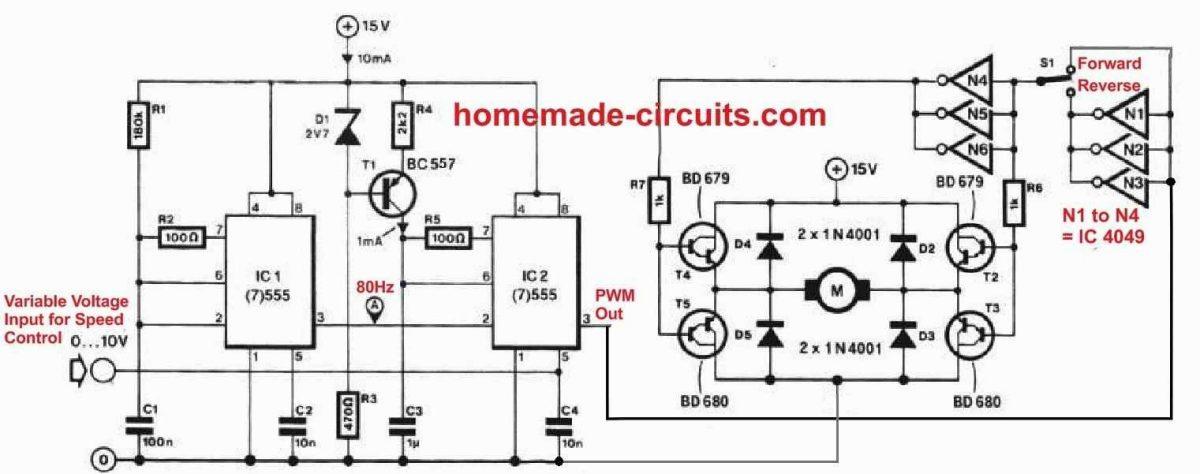

Now, let’s consider pulse width modulation. Think of it as rush hour on our highway. During this time, traffic alternates between moving and being at a standstill. Pulse width modulation adopts a similar approach but in a staggered and swift manner, rapidly switching the power supply on and off to control motor speed.

Both techniques culminate in effectively altering the power and torque of the DC motor, dictating its speed – an understanding that forms the bedrock of KB Electronics’ series of sophisticated DC speed controllers. If these principles of controlling speed pique your interest, you’re in for a treat as we tackle the nitty-gritty of some exceptional models in the next section!

What techniques does a DC speed controller employ to control motor speed?

Imagine driving a car without being able to adjust the speed, a bit chaotic, right? This is just like a Direct Current (DC) motor attempting to work without a speed controller. So just how does this clever piece of tech play the role of traffic controller to our manic motor, you wonder?

DC speed controllers are like the puppet masters of motors, controlling them through two major techniques: voltage control and pulse width modulation. It’s through these techniques that we can harness and utilize the power of DC motors in a more refined, efficient way.

Voltage control is pretty straight forward. If you liken the motor to a runner, then the voltage is like the runner’s energy level. If we increase the voltage or ‘energy level’, our ‘runner’ moves faster, and reducing it makes our ‘runner’ slow down. Would be easy to think that might be all there is to it, right?

Yet, there’s the other powerful technique, known as Pulse Width Modulation (PWM). With this fancy technique, the controller sends rapid voltage pulses to the motor. Now picture yourself cycling: the quicker you pedal, the faster you go. This is similar to PWM where the speed of our ‘bike’ (or motor) increases with faster voltage pulses.

So there you have it! Controlling speed with a DC motor is all about smoothly altering voltage or manipulating pulse frequency. If you ever find yourself standing before a piece of machinery marveling at its precise movements, you will now know who to give credit to – the humble DC speed controller! Remember, it’s not always about the muscle (or the motor in this case), but about who’s managing it!

Exploring the KBMD-240D: A Marvel of DC Speed Controller

Shining a spotlight on a notable example, let’s explore KB Electronics’ KBMD-240D Multi-Drive™ DC Speed Controller. This NYC-based technological champ is renowned for offering a remarkable blend of efficiency and simplicity. What makes the KBMD-240D stand out is its unique SCR (Silicon-Controlled Rectifier) technology. This nifty feature empowers the user to vary the voltage input, thereby deftly managing how does a dc speed controller work – from a subtle 1/100 to a whopping 2 horsepower!

The KBMD-240D is not just about power, though! Its user-friendly interface, coupled with a gamut of easily adjustable controls, makes it an absolute breeze to operate. Whether it’s ramping up the speed of your motor for a heavy-duty task or slowing it down for a meticulous operation – this ace DC speed controller holds its ground deftly. Looking past its specs, visiting kbelectronics.com also reveals a customer-focused company that values its users. It’s not just about creating an excellent product but also about enhancing user experience, making KB Electronics a go-to choice for many industries.

It’s a stellar example of the potential answer to “how does a dc speed controller work“. With every new innovation, we are witnessing DC speed controllers becoming more instrumental and reliable in the ever-advancing field of motor control. KB Electronics, with their continuous improvements and customer-centric approach, plays an integral role in these advancements.

What is SCR technology and how does it empower the KBMD-240D DC speed controller?

SCR Technology, short for Selective Catalytic Reduction, is a super cool system that reduces harmful emissions in engines. But you’re probably wondering, how does that connect with the KBMD-240D DC Speed Controller? Well, it doesn’t directly, but the concept is similar. Both work to make systems more efficient and reliable.

Just as SCR technology empowers engines to perform better, our dear old friend – the KBMD-240D DC Speed Controller – does so in the world of motor control. It uses a technology called PWM (Pulse Width Modulation) which is kind of like the SCR of motor control. Essentially, it helps manage the voltage and current supplied to the electric motor which in turn controls the motor’s speed. So, it’s essentially the heart of a motor system, making sure it hums along nicely.

The secret sauce of the KBMD-240D, and what really underscores its prowess, is the practical integration of the technology. It is designed to pack a punch in performance while being compact enough to fit into tight spaces, which we can all appreciate.

If you’re still trying to get your head around it, think of the SCR and the PWM as the dynamic duo powering the DC speed controlling world. Being able to understand and control your motor’s speed can be a game-changer. It’s like having your cake and eating it too. It’s the ultimate control, and that’s exactly what the KBMD-240D offers. Fantastic, isn’t it?

How DC Speed Controllers Work

Diving into the technicalities of a DC Speed Controller can be quite fascinating! One of its most critical functions is how consistently it maintains a constant speed, even when the load fluctuates. Imagine a symphony conductor coordinating a variable speed orchestra – the controllers work in a closely similar manner, adjusting their actions according to the need.

- Signal Processing: Just like the conductor who interprets the music score and gives the musicians cues on tempo adjustments, the controller processes feedback signals from the motor.

- Energy Influx Management: Now, think of a sudden change in the musical piece, which requires the violins to play faster. In an identical vein, with varying loads, the controller manages the energy inflow to the motor, ensuring a steady speed.

- Performance Optimization: Lastly, akin to the conductor keeping an eye on every performer for a harmonious execution, the controller continually monitors the motor’s performance, adjusting parameters for optimal efficiency.

Through these mechanisms, the motor’s speed is kept constant despite changes in power requirements, reflecting a true marvel of engineering. This is a primary reason why DC Speed Controllers are indispensable in industries, especially where changes in load can be erratic and frequent. As the KB Electronics’ website informs, their controllers’ advanced technology ensures reliable and steady speed control – a brilliant example of how does a DC speed controller work!

What industries require the use of DC speed controllers and why?

DC speed controllers are like the secret sauce in several key industries, making everything run just a bit smoother, a touch more efficiently. So, let’s break it down, shall we?

Right off the bat, the automotive industry comes to mind. From electric vehicles needing that little something extra to keep them humming along, to the systems within our car that need to vary their speed (think windshield wipers), DC speed controllers are pivotal. They provide that precision control over motor speed to make sure your sweet ride delivers an equally sweet performance.

Now, imagine powering up your home appliances. Whether it’s making your morning smoothie or whizzing up an evening soup in your blender, DC speed controllers give you control over the speed, allowing you to go from easy-peasy pureeing to serious slicing and dicing in seconds. So yes, they’re pretty pertinent in this sphere too!

In industrial setups – from manufacturing to conveyor belts – an optimized work process is everything. A DC speed controller lets users manage the speed of electric motors, balancing efficiency and performance.

So, you see, a DC speed controller isn’t just another chunk of circuitry; it’s an ingenious device that’s crucial to everything from a comfy car ride, a successful soup venture, to streamlined factory functions. Now, isn’t that something?

How does a DC speed controller work?

Now let’s turn our attention to where the magic happens. How does a DC speed controller work in real-life applications? You’d be surprised at how ubiquitous they are. Ever marvelled at the automated assembly lines in factories, or the seamless operation of your central heating and cooling system? Heck, even the electric vehicle that whizzed past you this morning owes its smooth ride to DC speed controllers. In fact, the US Department of Energy suggests that a staggering 65% of industrial power is consumed by electric motors, the heart of which is the humble speed controller.

- Industrial automation: Think conveyor belts, robotic arms, packaging systems. These all rely heavily on precision speed control.

- HVAC systems (Heating, Ventilation and Air conditioning): Your comfort at home or work is largely in the hands of DC Speed Controllers, managing the fans and pumps of these systems.

- Electric Vehicles: Smooth acceleration, regenerative braking, efficient battery usage – all thanks to speed controllers, making EVs a sustainable choice in transportation.

Incredible, isn’t it? We often overlook these behind-the-scenes heroes, but without the wholesome work of DC speed controllers, our world would look a lot less automated and a lot less comfortable. So the next time you switch on your air conditioning or see a factory in operation, just remember: Behind its seamless operation lies the question, “how does a DC speed controller work?”, and now, you know the answer.

What are some real-life applications of DC speed controllers?

DC speed controllers are truly handy gizmos that actually pop up in our daily lives quite often! Just think about the electric cars zooming past you on the streets; they use these devices to control the speed of their motors – all to give you that smooth drive you enjoy so much.

Think about those cool kids whizzing past you on their electric skateboards, popping off tricks – yup, you guessed it, those boards also have this bit of tech magic!

Ever taken a tour in an electric golf cart? Those also use DC speed controllers to provide you a serene tour of your golf course. And it’s not just moving vehicles, my friend. Ever tinkered with those automated machine tools at your makerspace or garage? Those use DC controllers to adjust the speed of the spinning bits and blades to just the right speed.

Heck, even something as simple as your home’s adjustable ceiling fan uses a DC speed controller to let you dial in the perfect breeze on a hot day. All these applications showcase the versatility and importance of DC speed controllers in making our lives convenient and efficient. Just goes to show how something so technical can directly touch almost every aspect of our lives, doesn’t it?

Discover the Inner Workings of a DC Speed Controller

As we move on with the world of technology ever-evolving, there are continuously newer and more efficient innovations hitting the market. One such noteworthy mention is the Microchip Technology’s MCP19111. Now, when it comes to the question, “how does a dc speed controller work?”, this device offers a fresh perspective that’s worth exploring. Hailed as the world’s first digitally-enhanced, programmable DC/DC controller, it has certainly injected a breath of fresh air into the world of DC speed controllers.

What sets MCP19111 apart is its unique blend of functions. For starters, it boasts programmability, allowing users to customize as per their specific needs. Not just that, the MCP19111 houses integrated MOSFET drivers, which do wonders in increasing the efficiency of motor operations. Plus, it’s equipped with a fully-fledged PWM generator.

It’s no wonder then that the MCP19111 is witnessing an upward trend in popularity among engineers and tech enthusiasts alike. So, if you’re someone who’s keen about understanding ‘how does a dc speed controller work?’, keep an eye on innovative breakthroughs like these.

What makes Microchip Technology’s MCP19111 unique as a DC speed controller?

The uniqueness of Microchip Technology’s MCP19111 as a DC speed controller lies in its innovatively mixed architecture. Let me explain. This piece of technology elegantly combines the ease and flexibility of a digital system with the sheer power and functionality of an analog one. It’s like getting the best of both worlds, right? Just imagine having the benefits of a microcontroller such as handling complex algorithms and precise control but also possessing the robustness of an analog system. This makes the MCP19111 outstandingly efficient and remarkably adaptive in managing power. And let’s not forget, it’s the first of its kind to provide this fusion! Sure, it can be a bit of a brain teaser getting your head around the in’s and out’s of a DC speed controller, but once you grasp the concept, it’s a real game-changer! The MCP19111’s hybrid design offers ideal control of speed, power, and efficiency, making it the perfect companion in the age of smart technology. With this little marvel, you can truly master the nuances of speed control like never before!

Looking ahead to the future, it seems like the adage ‘The sky’s the limit’ might be a modest prediction when you consider the bounds of possibilities that technological advancements could bring to the functionality and capabilities of DC speed controllers. With the constant evolution and innovations within the industry, there’s an expectation that these intricate devices will only continue to improve, giving us even greater control over motor speed. Research and development are continuously pushing the envelope on what we know about ‘how does a dc speed controller work’, striving to make these essential pieces of equipment more efficient, more reliable, and even more versatile.

As we come to terms with the fascinating workings of a DC speed controller — its technical nuances, significant models like the exceptional offerings from KB Electronics, and its myriad applications, from industrial automation to electric vehicles — it’s clear that these impressively complex devices play an integral role in modern life. They’re the unsung heroes behind other technologies we take for granted daily, quietly ticking along and making our lives easier without most of us ever being aware of their presence.

In conclusion, understanding ‘how does a dc speed controller work’ presents a fascinating deep dive into an important cornerstone of technology, underpinning so much of our modern lives. As we continue to refine and improve these devices, who knows where the future might take us? Here’s to embracing the future of DC speed controllers with open arms.